How to Effectively Train Manufacturing Employees (+Challenges)

- November 29, 2022

Manufacturing is one of the most operationally-intensive sectors. According to McKinsey, such sectors have 1.3x the automation potential compared to others, less operations-intensive sectors. By implementing digital solutions and technologies to automate operations, we can dramatically boost the efficiency of manufacturing processes.

However, the same report shows us that this automation and digitalization of manufacturing have drastically shifted the skill requirements needed for job roles. That’s because all the new tools and technologies will work only if they’re implemented and operated by a trained, upskilled workforce.

Let’s dive in and see how to train employees at manufacturing facilities, and the benefits you’ll receive from it.

5 Challenges of Training Manufacturing Employees in 2023

First, let’s look at some of the most significant manufacturing training challenges L&D professionals should expect to face:

1. The need for reskilling and upskilling for new digital technologies and processes

As we mentioned above, the new technologies introduced in manufacturing facilities have created a skill gap that needs to be filled. As a result of this skill shift, managers and L&D professionals need to reassess their employee training processes and start reskilling and upskilling their workforce in new digital skills and technologies.

2. Creating role-based learning programs

Another struggle manufacturing companies often deal with is using a job role-based approach to learning, training, and career development. This type of personalized learning produces much faster results than generic training.

3. Providing on-demand employee performance support post-training

Improving employee performance in manufacturing is not a one-time event after which you’re off the hook. On the contrary — it’s an evolving process that starts with onboarding and training, and continues into ongoing performance support. Unfortunately, this is a fact that many L&D professionals and managers dismiss or lack the structure to establish.

4. Measuring training effectiveness

Many manufacturing facilities can conduct great employee training programs. However, they don’t excel in tracking, gathering data, and measuring these efforts. L&D professionals need to ask themselves, “what objectives, goals, and KPIs will we use to track the progress and success of our training?”

5. Training distributed workforces

Many manufacturing facilities can conduct great employee training programs. However, they don’t excel in tracking, gathering data, and measuring these efforts. L&D professionals need to ask themselves, “what objectives, goals, and KPIs will we use to track the progress and success of our training?”

Benefits of Training Employees at a Manufacturing Facility

The importance of training your manufacturing employees is undeniable in today’s Industry 4.0 — with the boom of digital information. Some of the essential benefits of manufacturing employee training are:

- Develops internal employees into future leaders: It’s a well-known fact that recruitment costs more than retention. So, by upskilling your employees in new technologies, or reskilling them based on their strengths and preferences, you’re drawing the best out of every role.

- Identifies competency and skill gaps: Establishing a manufacturing training program will inevitably lead to pinpointing skill gaps and discovering learning needs.

- Shows employees you’re investing in their development: Your manufacturing employees need to feel appreciated and empowered. They need to know that career growth and income growth are real possibilities. According to a 2022 Deloitte and The Manufacturing Institute report: “fifty-eight percent of surveyed respondents feel manufacturing jobs have limited career prospects, but 80% might be interested in roles with enhanced training and clear career paths.”

- Reduces employee turnover: Lack of career advancement opportunities and absence of engagement are the main culprits for high employee turnover. One of the best employee engagement ideas is to provide continuous training, learning, and development opportunities, especially in a sector like manufacturing that’s constantly growing and evolving.

- Improves performance and productivity: By training your manufacturing employees, you automatically make them better at their jobs, and boost their performance and overall productivity — resulting in a competitive workforce.

- Shortens time-to-proficiency: Introducing a manufacturing training program during the initial stages of employee onboarding will shorten the time new hires need to adjust, adapt, and start working productively with the rest of your crew.

- Improves workplace safety: Manufacturing employees with the proper training and maintenance certifications greatly upgrade workplace safety. Although this is of key importance for all sectors, it’s essential for manufacturing where staff operates with heavy machinery and faces production line hazards daily.

10 Best Practices for Training Manufacturing Employees

Now that we’ve seen all the challenges and benefits of employee training in manufacturing, let’s look at some of the best practices you can implement to provide their development in the upcoming 2023:

1. Perform a training needs analysis

First and foremost, you should start by conducting a training needs assessment to identify the skill gaps you need to fill. In other words, you’re now looking for all the “problems” that need fixing.

At this stage, you should ask the following questions:

- Which processes have unresolved bottlenecks and weaknesses?

- Who needs training (the staff that performs the operations that need fixing)?

- What is the task or activity you’re training the employee for?

Here’s where you want to think of role-based training, as not all employees need the same skills.

✓ Thank you, the checklist will be sent to your email

2. Set training goals, KPIs, and objectives

Before the training are completed, you’ll need to find a way to measure its success and effectiveness. You’ll need to set up a structure of employee training goals, objectives, and KPIs well in advance.

You will need to answer these four questions:

- What’s the objective of the training?

- What is the business goal you’re hoping to achieve?

- What metric or KPI is most suitable to track the progress of your goal?

- What analytics tool will you set up to record and track this progress?

If you don’t have a clear answer to all four of these questions, you might struggle to understand the success of your training.

3. Invest in employee training software

Training manufacturing employees, especially those part of a large organization, could be virtually impossible without proper employee training software.

HR teams and L&D professionals use different tools to create, assign, manage, and monitor the progress of training employees. Your goal here should be to standardize the entire training process to boost its effectiveness.

Some great features that add to the usefulness of employee training tools are:

- Mobile and on-demand training

- Employee onboarding faciliation

- Remote training

- Performance support

- Software user adoption

- Interactive learning

- Tracking and analytics

When faced with the challenge of training a large number of employees, a tool like this is not a luxury — it’s a requirement.

4. Provide various training methods and formats

A training delivery method represents how you communicate new information to employees in a way that’s understandable and easy to learn and memorize. The first thing to consider here is that not everyone receives and retains information the same way. Some employees are visual learners, while others might remember better if they read or listen to something.

On top of that, not every type of training requires the same training delivery method.

That’s why when training manufacturing employees, we suggest a holistic approach or a combination of some of these employee training methods:

- One-on-one training

- Instructor-led group training

- Written training materials

- Video, animation, images, infographics

- Webinars

- Mentoring or shadowing

- Simulation training or role-playing

Naturally, not every manufacturing training will require all of these methods. Your goal should be to find which method (or combination of methods) is most appropriate based on your training goal. These types of blended learning solutions will generate the best results.

5. Create personalized learning paths based on roles and responsibilities

Training manufacturing employees shouldn’t be a one-size-fits-all approach. Different roles require different training methods.

For instance, considering that safety is of utmost importance in manufacturing, designing a proper maintenance training program that includes hands-on training is a must for workers. On the other hand, your manufacturing team leader or supervisor will probably need a different type of training.

Here are some tips to help you create optimal personalized learning paths for your manufacturing employees:

- Create a vertical upskilling path for each job role

- Create horizontal reskilling learning paths for job roles that are closely related or intertwined

- Pay attention to the skill gaps you need to fill

- Use employee feedback and track efforts to continuously improve your training program

- Consider the career goals of individual employees

6. Break your training up with microlearning

Our attention span nowadays isn’t what it used to be. Thanks to social media, we’ve gotten used to consuming bite-sized pieces of content that are easy to absorb. Instead of reading through articles, we skim through the subheadings. Instead of reading, we listen to a podcast while driving.

In regards to employee training (in manufacturing and otherwise), microlearning carries the same philosophy. It’s a way to break down large and complex information into smaller modules that are easier to digest and comprehend.

Many microlearning examples show the benefits of this way of training:

- Real-time learning that’s accessible exactly at the moment when the employee needs it

- A greater psychological engagement which boosts the training completion rate

- Implementing learning into practice right away (better for knowledge retention)

- Less time-consuming for both sides (for the L&D professional to create the materials needed, as well as for the employee to absorb the information presented)

- Wide application as stand-alone pieces of information or combined into a more extensive training program

- Often used on a mobile app for accessible help on the go

7. Use training analytics to measure effectiveness

Training or learning analytics are there to measure the effectiveness of an employee training program and improve its ROI ultimately.

Some of the employee training software will include training analytics as a feature. However, if you need to do this manually, here are some metrics to help you measure training effectiveness:

- The pre-set training KPIs or the metric you’re going to use to measure

- Quizzes, surveys, and questionnaire results

- Performance-based data

- Informal feedback

8. Ask for post-training employee feedback

The best way to continuously improve and upgrade your learning program is to encourage open and honest feedback loops. You can do that by encouraging the employees to:

- Complete post-training surveys or questionnaires after each training module

- Give suggestions and improvement ideas

- Encourage open communication and ask employees about their career goals

- Listen to what your staff has to say and implement the suggestions when viable

9. Communicate any process or technology change and provide additional training

Just like the manufacturing sector itself is constantly evolving, training manufacturing employees is a never-ending process — look at it as continuous upgrading.

There are new solutions, digital technologies, and software coming out every day on ways to make your manufacturing facility more efficient. All these new tools have a learning curve that often requires additional training.

When introducing a new operation or software to your manufacturing employees, don’t forget to communicate it in advance and provide the needed onboarding process. This requires a change management strategy to anticipate resistance to change by facilitating a smooth transition focusing on the benefits of a new process or technology.

10. Provide continuous, on-demand employee performance support

Last but not least, you should keep in mind that manufacturing training isn’t a one-time thing but a continuous effort of testing and improving.

The manufacturing sector is still developing and going through a digital transformation with more and more technology and tools becoming available to simplify operations and make organizations more efficient.

As a result, if you wish to keep up with the competition and stay relevant, you must upgrade and perfect your training materials continuously along the way. That’s why it’s so crucial to find a way to design a self-service knowledge base that your manufacturing employees can use on demand.

One of the best ways to do that is by implementing a quality performance support system that will give your manufacturing staff the autonomy to learn and refresh their knowledge as needed.

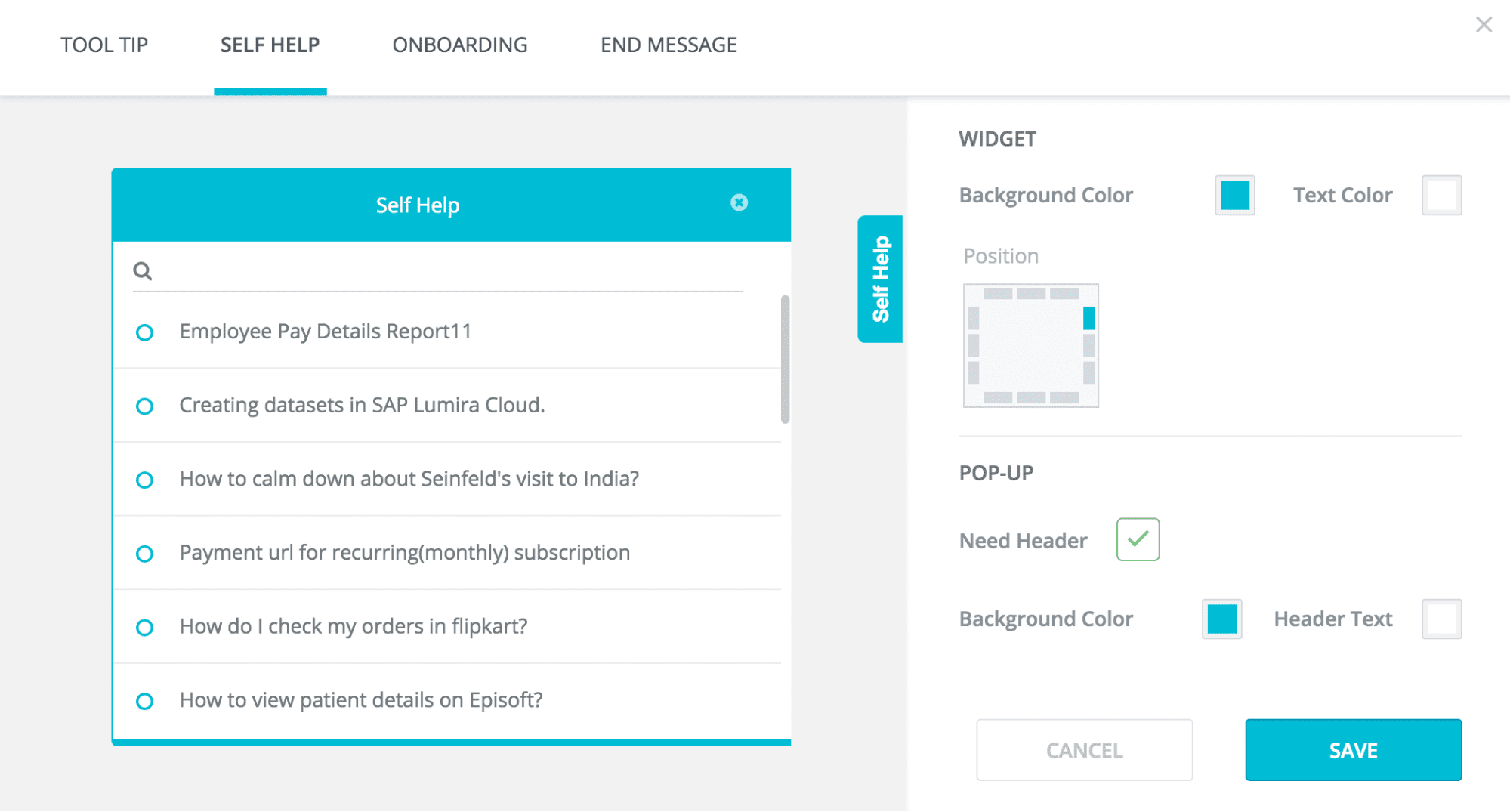

With Whatfix, provide your manufacturing employees with in-app guidance that enables them to find real ROI with the digital tools and processes they use each day.

With Whatfix’s on-demand, self-help support, employees are empowered with contextual help, right at the moment of need, without leaving their applications.

With Whatfix Analytics, understand how your employees and end-users are adopting and engaging with your software, helping you to identify underutilized features and product friction points, ultimately driving overall software adoption across your organization.

Thank you for subscribing!