Digital Transformation in the Automotive Industry (+Examples)

- Published:

- Updated: April 18, 2024

Digital technologies are transforming the automotive industry. Manufacturing plants now use connected systems and data analytics to increase efficiency. Showrooms use software to improve sales and customer experience.

As competition rises and consumer expectations grow, automotive companies must embrace digital transformation to remain competitive. Relying solely on mechanical engineering and outdated business processes isn’t enough. Success requires digital capabilities.

This article explores digital transformation in the automotive industry. It looks at how technology is changing manufacturing, sales, and beyond. The focus is on breaking down the industry’s key components, use cases, and real-world impacts. We’ll examine what’s driving this shift and where automotive is headed.

What Is Digital Transformation in the Automotive Industry?

Digital transformation refers to automotive companies integrating modern technologies across vehicles and business operations. The goal is to improve efficiency, meet consumer expectations, and position for the future.

This can involve using connected systems and data to boost production quality and output in manufacturing. Vehicle designs may also incorporate new materials and methods. In sales, dealerships may utilize interactive displays and tools to cater to tech-savvy buyers. The focus is on providing a personalized, streamlined experience.

Within vehicles, connectivity platforms and advanced driver assistance systems aim to enhance convenience, safety, and mobility. This stretches technical innovation through the customer journey.

Combined, digital integration aims to help automotive companies meet the pace of change across the industry. They hope to increase agility and sustain innovation from factory to driveway by upgrading key functions with new technologies. The end goal is to stay competitive as software and technology reshape transportation.

Benefits of Digital Transformation in the Automotive Industry

What can you expect as you shift focus to digital transformation? Take a look at some of the most common benefits.

1. Streamlined supply chain

The traditional model of complex automotive supply chains and logistics is transforming through newer digital capabilities. For example, IoT sensors and supply chain data platforms provide real-time visibility into parts moving through the ecosystem. This reaches beyond modernizing processes. It represents an organizational commitment to boosting efficiency.

As digital transformation in automotive progresses, supply chain improvements go hand in hand. Manufacturers balance adopting new technologies with strategic partnership-building across their supplier networks. All to increase speed and transparency while nurturing collaborative relationships. This is critical in an industry where agility is key.

2. Improved product quality management

Automotive companies often rely on manual inspection and reactive approaches to address quality issues. Digital transformation introduces more proactive management powered by IoT, automation, and analytics. Connected sensors enable constant monitoring for calibration deviations or equipment anomalies. This prevents defects and avoids costly rework.

3. Reduced operational costs

Controlling costs while increasing output has challenged automotive manufacturers. These are some ways digital tools and systems can help:

- Smart building upgrades save energy

- Forecasting software reduces waste

- Augmented reality training improves productivity

Seeing these benefits and transitioning to more technology requires balance. Understanding workforce barriers makes adoption smoother and gradual rollout helps manage the change as a whole.

4. Enhanced customer experience

Connected vehicles and virtual showrooms provide new ways to enrich the experience. Combining digital options with emotional intelligence and consultative service from sales reps is critical as digital options grow. Blending convenience with genuine care from your team builds loyalty.

That said, while new tools are essential, it’s just important to understand how they fit into the bigger picture. Digital systems enhance human decision-making, but it doesn’t replace that. Employee buy-in is what makes improvements and digital adoption possible.

Challenges of Digital Transformation in the Automotive Industry

There are often major roadblocks that can hinder digitalization success. Here are a few challenges to be aware of and strategies you can use to overcome them.

1. Cybersecurity and compliance

While connectivity and data offer automotive companies valuable insights, more attack surfaces also increase cyber risk. As vehicles and production facilities digitize, thorough cybersecurity protections are non-negotiable.

This includes training employees on threat detection, patching known vulnerabilities, monitoring networks for irregularities, and maintaining compliance as regulations evolve. Companies can’t afford to skip this step, because of those that recently suffered a cloud data breach, 55% of respondents identified human error as the primary cause.

Applying a “security by design” approach from the initial phases can help avoid retrofitting issues. Some best practices include penetration testing new systems pre-launch, restricting access through the principle of least privilege policies, encryption to protect sensitive data, and contingency planning for possible breaches.

2. Reskilling and upskilling

The technologies transforming automotive also require workforce enablement. Significant reskilling and upskilling are crucial as job roles shift and expand to use new capabilities. The scale of these programs depends on leadership buy-in alongside detailed assessments to map emerging skills gaps.

Companies that fail to train teams with contextual onboarding and learning risk the success and adoption of new tech-driven processes, especially if your workforce doesn’t have foundational digital skills. Training initiatives like the National Apartment Association education programs are crucial for developing digital literacy to leverage sophisticated software and tools. Consider hiring a digital transformation consultant to assist with reskilling and education for your digitization.

Furthermore, a digital adoption platform (DAP) like Whatfix allows companies to create in-app guided experiences like Tours, Task Lists, Flows, Self Help, and more that enable end-users with contextual, moment-of-need support that enables them to utilize digital applications and their contextual workflows fully.

3. Enabling technology end-users

While digital solutions aim to empower end-users through greater independence and convenience, poorly implemented tools can backfire, causing confusion and frustration. User experience testing, co-creation sessions, and training programs help to support engagement.

For example, dealerships rolling out new customer-facing technologies often assemble pilot groups for feedback. Manufacturers bring production floor workers into design decisions for new autonomous systems. Empathy for those interacting with complex hardware and software underpins successful adoption.

With Whatfix, track and analyze end-user actions with User Actions. This uncovers areas of end-user friction, maps user flows, builds user cohorts, and more. Use this data to create new in-app guidance and end-users and continuously optimize and test new workflows and features.

Software clicks better with Whatfix's digital adoption platform

Enable your employees with in-app guidance, self-help support, process changes alerts, pop-ups for department announcements, and field validations to improve data accuracy.

4. Technology cost

Transitioning from legacy processes requires significant initial investments that may strain budgets. One report found that the average digital transformation project can cost enterprises $27.5 million. IDC predicted global spending on digital transformation initiatives and related costs would reach $2.3 billion in 2023.

Even though there is a high digital transformation cost, failing to fund digital transformation initiatives impacts competitiveness longer-term. Companies can explore financing options to ease near-term cash flow pain points.

When done right, scaling new technologies also unlocks additional efficiency gains over time that close spend-benefit gaps. Pursuing a phased IT modernization roadmap helps balance revamping high-impact areas first so that innovation can happen in waves.

Examples of Digital Transformation in the Automotive Industry

How do these new technologies change operations from the shop to the dealership and beyond? Look at some of the ways digital transformation is reshaping the automotive space.

1. Digital retailing

The rise of e-commerce has reached automotive sales, with dealerships adopting online platforms for browsing inventory, customization, and even full transactions. This shift to digital retailing caters to buyer preferences for convenience while streamlining back-end sales processes. Customers can explore vehicles on their own time and complete paperwork digitally.

The popularity of digital retailing is booming. Online vehicle retail, aftersales, and services are forecasted to continue to acquire market share, and the global revenue from online vehicle retail is expected to increase fivefold, from $120 billion in 2018 to $605 billion in 2025.

Still, transitioning to online sales comes with adoption challenges, from older demographics preferring in-person experiences to back-end integration with legacy dealer management systems. However, failing to offer some degree of digital retail presents the risk of losing ground to disruptive online-only alternatives entering the market.

A mid-sized GM dealer needed a better way to engage with live customers on their website. Form fields needed to perform better and produce quality conversions. Oncethe form submission hit the dealer’s CRM, staff spent much time calling and emailing customers to re-engage.

The dealer implemented a connected retail solution using CarNow’s Real-Time Retail™ platform. In just 2 months they saw results, including a high closing rate. CarNow also helps the dealer have a 62% higher number of vehicles sold than their next highest lead source.

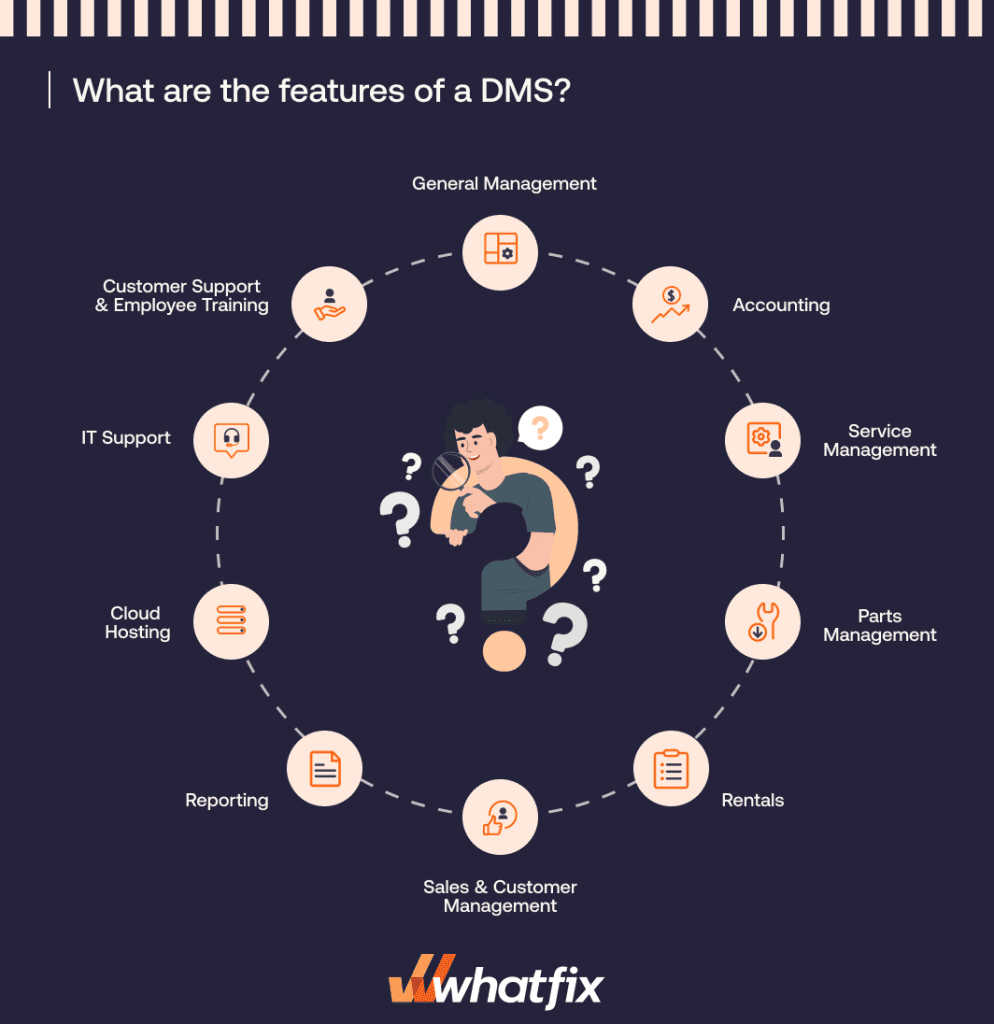

2. Dealership management systems

Dealership management software has become mission-critical for optimizing inventory, CRM, accounting, and service scheduling. Consolidating these capabilities into one unified system with deep analytics enhances visibility and efficiency. However, switching from paper-based processes remains challenging, and connecting data sources can be tricky.

In the not-so-distant past, it wasn’t possible to have access to all customer insights with a single click or tap. The dealer management system market is growing at a CAGR of 11% from 2022 to 2030. It’s expected to reach a value of $18.2 billion.

This is changing the way dealerships operate. Honda UK Manufacturing wanted to improve communications with its dealer network, which posed several challenges. The key challenge was that many of their 200 dealers use different dealer management systems (DMS), preventing easy and quick communication and information sharing. Many of them had different designs, coding standards, business rules, and variable options for data export, with a big margin for error.

ETL Solutions allowed the company to cost-efficiently combine data from diverse dealer management systems to achieve network integration and provide a better experience for staff and customers.

Effective change management ensures teams use the data and insights these platforms provide. Dealerships should phase integrations starting with the highest pain point areas and provide ongoing training. When functionality improves, adoption momentum typically follows across most users.

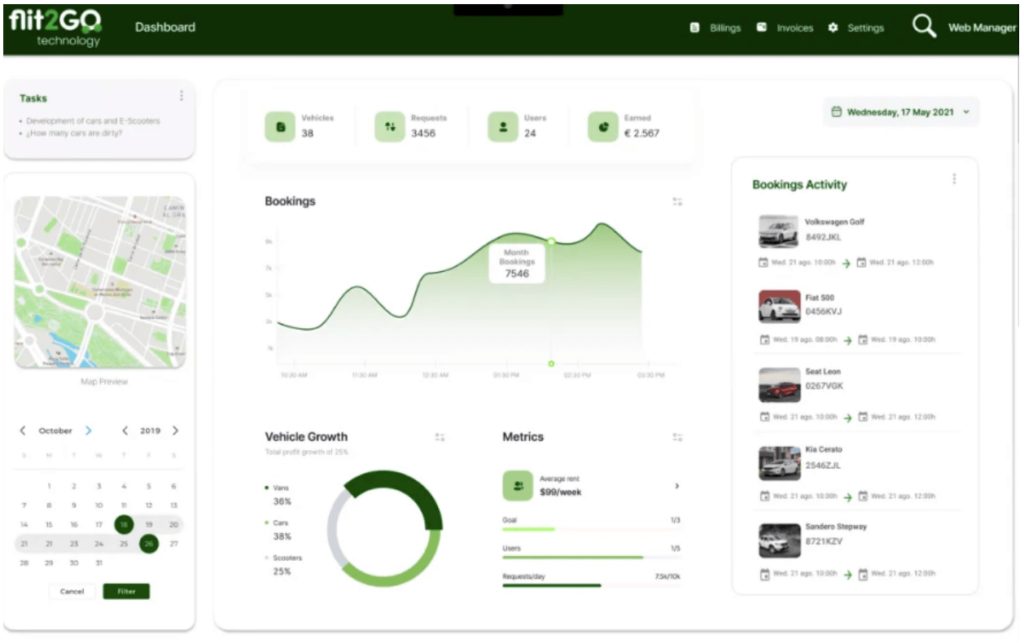

3. Car rental software

Advances in car rental software are driving improvements in how rental car companies manage their inventory. Systems can track vehicles in real-time, forecast demand more accurately, and optimize availability. This allows companies to increase fleet utilization rates and revenue.

In particular, machine learning algorithms can analyze past rental and return patterns to predict future demand more precisely. The software also enables dynamic pricing and easy-to-use payment options.

Using Rental Car Manager, businesses can specify what portion of the rental fee they charge when reservations are made. Credit card information is securely stored for easy re-billing as needed.

4. Predictive Maintenance

Using connected sensors and AI analysis, automotive companies can preempt mechanical issues before they trigger system failures. This shifts vehicle repairs from reactive to proactive, boosted by insights that manual service records don’t provide. Health monitoring and diagnostics also provide a differentiated customer experience while reducing business downtime.

According to Deloitte, on average, predictive maintenance increases productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%. This can make a big difference in a company’s bottom line.

A major car manufacturer avoided $0.5M in unplanned downtime and maximized equipment life with GraceSense™. Powerful data-driven decision support tools provide asset managers, engineers, and operations and maintenance teams with real-time information to make informed operational decisions.

They use an integrated system of wireless sensors, cloud-based storage, and advanced analytics to improve the predictive maintenance program and mitigate potential equipment failures.

Note that these predictive models rely on quality data flows from sufficient sensors across enough vehicles for pattern detection, which means you need clean and current data. That behind-the-scenes infrastructure enables the capabilities end-users eventually touch. Scaling this links AI’s potential to real-world reliability improvements over time.

With a DAP like Whatfix, ensure your data is clean with Field Validations and Smart Tips. Field Validation alerts end-users with error messages to ensure fields are entered incorrectly, not at all, or in the wrong format. Smart Tips provides contextual information on how to enter information correctly.

5. Automated storage and retrieval

Warehouses are transforming operations via automated storage and retrieval systems. These robotic platforms efficiently handle inventory replenishment, order picking, and component storage, optimizing space while reducing manual efforts and errors.

For example, Ford acquired three Modula Lift modules to complement the automated solutions at their plant in Almussafes, Spain. The Modula VLMs could place parts aside for later retrieval when the production line stalled and deliver parts as needed throughout the manufacturing process.

The VLMs integrated with anthropomorphic robot arms and Modula’s WMS enabled the company to run on a six-day-a-week continuous cycle, producing 17,250 engines a week. Modula VLMs also allowed Ford to optimize floor space, with 260 engine blocks stored in 14 square meters of warehouse space.

Manufacturers gain inventory visibility and boost throughput by automating repetitive supply chain tasks. However, retrofitting legacy warehouses can be cost-prohibitive, especially for smaller suppliers. A staged deployment focused on the highest transaction zones first can deliver benefits without overstretching budgets.

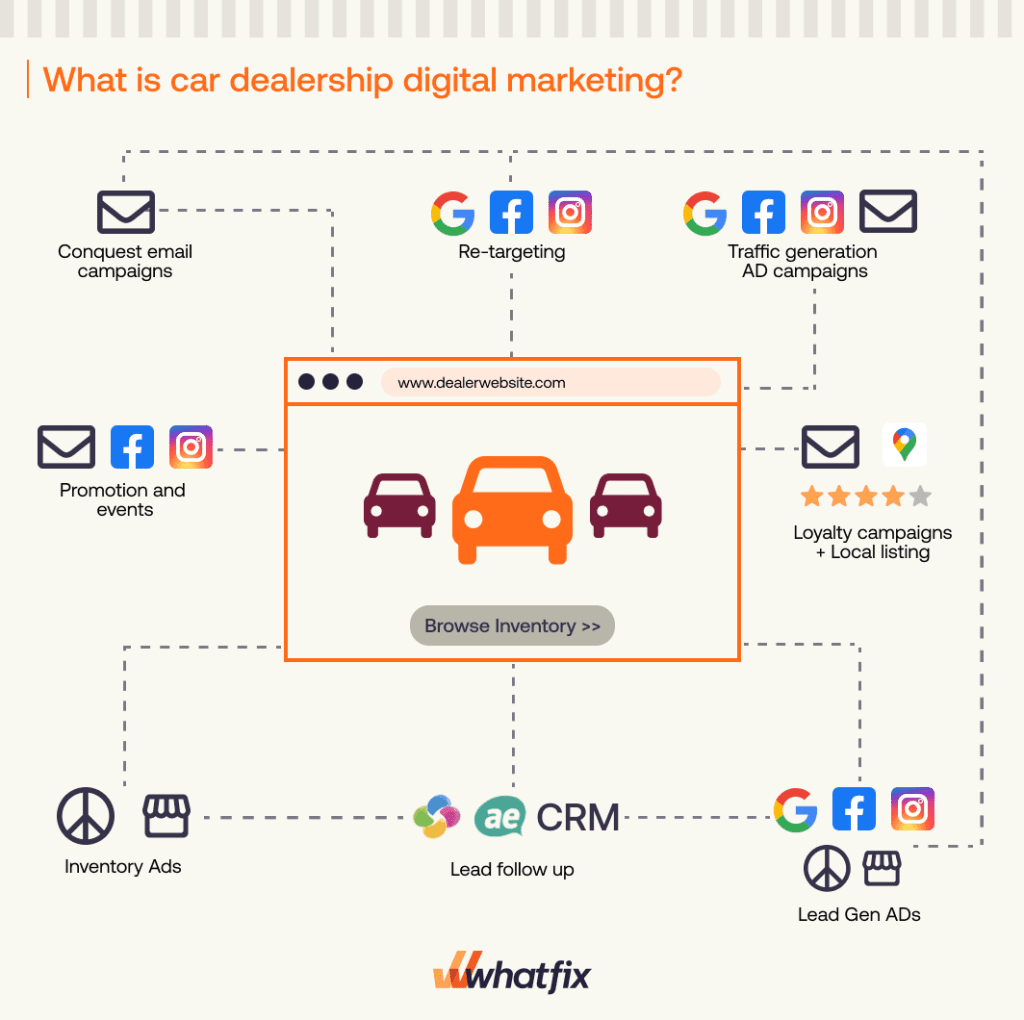

6. Automotive marketing software

Sophisticated marketing automation tools allow automotive companies to track customer interactions and target personalized campaigns across digital channels. Data and AI analyze performance, guiding strategies to boost engagement.

For example, with VinSolutions, one dealership has complete control over the experience customers have after their initial contact. The dealer group can now administer its own workflows, create and change CRM processes, and set up text and email campaigns. The flexibility has provided significant benefits to dealership employees and the auto group’s many customers, who now enjoy a better customer experience.

It’s worth noting that simply purchasing the newest software won’t drive results that align with overarching business objectives. Companies should first map desired outcomes, identify current capability gaps, and implement platforms purposefully. Combining technology and strategy is what leads to efficiency.

Digital transformation is challenging, costly, resource-intensive, and has lengthy implementation and migration cycles. Accelerate your automotive digital transformation by enabling your automate company employees and customers with contextual in-app guidance and real-time support with Whatfix’s digital adoption platform (DAP).

Whatfix provides automotive-based organizations with a no-code editor to create in-app, moment-of-need support and contextual guidance for end-users, both employees and customers, on all new dealer management software and customer-facing automotive technologies and process changes. This reduces time-to-proficiency and achieves new levels of productivity and proficiency through better software adoption, as well as provides customers with self-service, personalized, and guided user experiences.

Whatfix empowers automotive organizations to:

- Create in-app Flows and Task Lists that guide employees and customers step-by-step through digital processes and applications.

- Enable end-users with Self Help, providing a searchable help wiki that connects to all your help and support documentation, FAQs, help desk articles, and more – that overlays on your digital UI.

- Notify end-users of application process updates, compliance changes, company announcements, and more with Pop-Ups and Beacons.

- Provide contextual Smart Tips that enable end-users with timely information that nudges the to take the correct in-app action.

- Use Field Validation to ensure data is entered in full, in the correct format.

- Collect end-user feedback such as NPS, training and onboarding feedback, and bug identification with In-App Surveys.

- Analyze end-user behavior with User Actions and Enterprise Insights by tracking custom in-app events to optimize user journeys, segment users into cohorts, identify areas of friction, and more.

With Whatfix, you can understand how technology is being used and what is being underused. This makes it easier to adjust software training and adoption strategies—all to empower manufacturers, customers, and dealership owners to maximize the value of digital tools.

Thank you for subscribing!