Digital transformation in engineering isn’t only about adopting new technologies. It’s changing how we design and construct everything from skyscrapers to smartphones. But what’s driving this shift and what’s necessary for engineering firms to be successful?

In this article, we’ll explore digital transformation in this space. We’ll look at the benefits you can expect. Plus, we’ll cover the challenges you should be aware of and real-world examples of transformation in the industry.

What Is Digital Transformation in the Engineering Sector?

Digital transformation is changing every aspect of the industry. At its core, digital transformation in engineering refers to the strategic integration of digital technologies into traditional engineering practices and processes.

For example, engineers can use cutting-edge technologies like computer-aided design (CAD), simulation software, and advanced analytics. This accelerates the pace of innovation. It makes new levels of precision and accuracy in engineering projects possible.

Digital transformation can also make the industry safer for all. For example, predictive maintenance systems use machine learning algorithms to anticipate equipment failures. That minimizes downtime. Digital platforms enable engineers to streamline processes and drive innovation at every project lifecycle stage. Digital transformation can also contribute to a culture of collaboration, empowering teams to work together from any location.

Benefits of Digital Transformation in Engineering

Digital transformation is changing how projects are executed, and delivered. Want to know what to expect in your organization? Take a look at these common benefits of digital transformation in engineering.

1. Increased efficiency

Using automation and optimization tools, you can streamline processes and maximize productivity. For instance, computer-aided design (CAD) software powers rapid prototyping and iteration.

Integrated project management platforms also support coordination between team members. This helps to ensure that projects stay on track and schedule. The efficiency gains that engineering organizations see lead to better business outcomes.

2. Improved collaboration

Digital transformation breaks down geographical barriers, which makes it easier for team members to collaborate. You can share ideas and exchange feedback in real-time. This can speed up project timelines and reduce the risk of information falling through the cracks.

Modernizing collaboration is increasingly important, as one study by Gartner shows that after the first 18 months of the pandemic, 80% of workers reportedly used digital collaboration tools, up from 40% at the start of 2020. These numbers are likely to continue to rise.

3. Identifying issues faster

Digital transformation equips engineers with tools that help them proactively uncover issues and make changes. With IoT sensors and monitoring systems, engineers can monitor equipment performance in real-time.

Digital Transformation Challenges in Engineering

As organizations strive to modernize, they also encounter challenges. Here are the challenges that you should be aware of.

1. Resistance to change

Research shows that digital transformation efforts fail about 70% of the time. However, that’s largely because users hesitate to adopt new technology and embrace digital tools. The way leaders approach change management makes an impact.

Motivating the widespread adoption of new technologies is only possible by clearly demonstrating how the tools will enhance existing workflows without disruption or compromising quality. Engineering professionals must know how these systems impact workflow and the client experience.

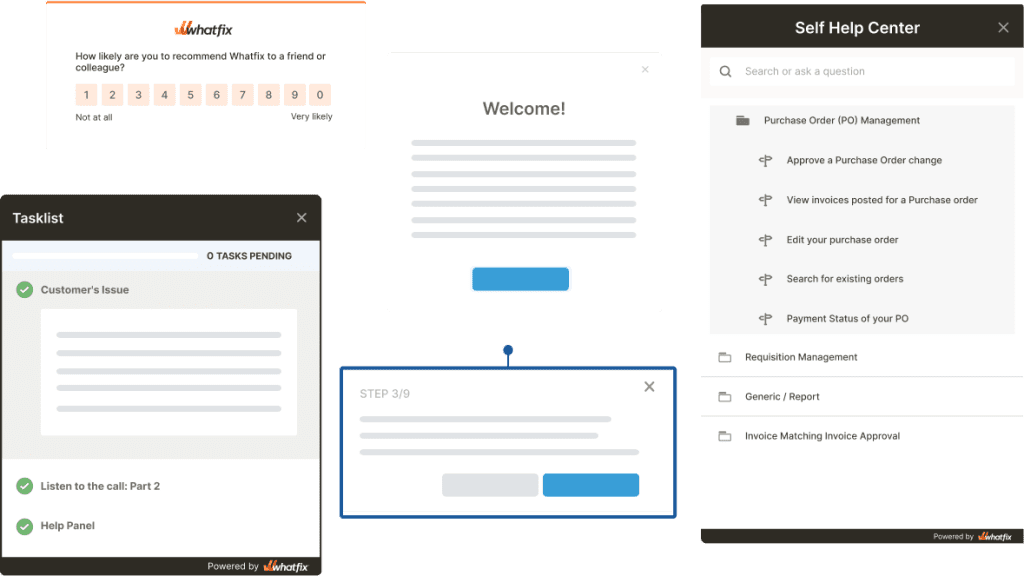

With Whatfix’s digital adoption platform (DAP), enable your technology end-users with contextual in-app guidance and moment-of-need support. With Whatfix’s no-code Visual Editor, non-technical team members can create in-app experiences that engage and assist users in the flow of work.

With Whatfix, create:

- Tours and Task Lists to contextually onboard new end-users to legal technology with a guided experience.

- Flows that take end-users step-by-step through their tasks and help drive the adoption of complex, multi-step workflows through in-app training.

- Smart Tips that provide additional support and relevant information at the moment of need.

- Pop-Ups to make company announcements, remind employees of upcoming deadlines, drive awareness of new features or process changes, and more.

- In-app Surveys to capture feedback from construction firm employees and customers interacting with your digital experiences.

2. Integration with existing systems

Large organizations use an average of 367 different software tools. This creates data silos that disrupt processes and block collaboration across teams and departments. Bridging these gaps requires policies for data access and infrastructure consolidation. It also means ensuring digital tools are compatible with one another and your processes.

3. Data security

The amount of data that organizations need to manage grows every day. By 2025, global data creation will grow to more than 180 zettabytes. Ensuring your data remains secure is critical for maintaining trust and legal compliance. Cybersecurity measures like access controls and risk monitoring, must exist across all digital platforms and tools.

Examples of Digital Transformation in Engineering

What does engineering digital transformation look like in practice? Consider these examples of how cutting-edge technologies are reshaping the way engineers work.

1. Computer-aided design (CAD)

CAD software empowers engineers to conceptualize and refine designs with speed and precision. From simple 2D drafting tools to sophisticated 3D modeling platforms, CAD drives modern engineering.

Using solutions from companies like Autodesk, it’s possible to empower design and engineering teams to concentrate on groundbreaking solutions by using automation to minimize errors and time spent on repetitive tasks.

2. Computer-aided engineering (CAE)

CAE tools help professionals simulate and analyze the performance of engineering designs under various conditions. CAE empowers engineers to identify potential flaws and accelerate the development cycle.

For example, CAE solutions from AWS create production-ready environments for design, simulation, and analysis workloads. Using these solutions simplifies the management of high-performance computing. They can also help deploy cloud-based workstations for product design processing.

3. Predictive maintenance

A data-driven approach allows you to forecast maintenance demands and proactively address issues. Predictive maintenance models help engineering firms gain insight into potential failures before they occur.

ServiceMax helps organizations extend the life of assets in the field, grow contract value, and improve satisfaction. In fact, the average customer increases service revenue by 25% and improves equipment uptime by 12%.

4. Building information modeling (BIM) software

BIMs are virtual modeling software that allows collaborators to collectively visualize, test, or simulate design-build concepts in detail. This single source of truth drives informed planning. BIM software often links to other core solutions, including project management tools. That supports an intelligent and connected construction software stack.

For example, SketchUp makes it possible to fully immerse stakeholders in the vision with 2D plans, 3D walkthroughs, mixed reality viewing, and more. You can also manage access to projects, mark up models, and sync files in the cloud for feedback.

5. Mechanical design automation (MDA) software

MDA software automates repetitive design tasks and calculations. This frees up engineers to focus on creative problem-solving.MDA tools speed up the generation of complex mechanical designs and documentation. This improves accuracy and accelerates time-to-market.

For example, Solid Edge uses synchronous technology to accelerate product design, make revisions faster, and improve design data reuse. With faster 2D drafting, sheet metal design, flexible part, and assembly modeling, built-in photo-realistic rendering, and unmatched mobility.

6. Integrated electronic CAD (ECAD) software

From schematic capture and thermal simulation, ECAD tools offer capabilities for designing complex electronic systems. By integrating with mechanical design and simulation software, ECAD supports collaboration and the integration of electronic components.

Ansys Sherlock is a physics-based electronics design tool that provides fast and accurate life predictions for electronic hardware at the component, board, and system levels in early-stage design.

7. 3D modeling software

3D modeling software allows engineers to create detailed virtual representations of physical objects and environments. Engineers use 3D modeling software to visualize concepts and communicate ideas effectively.

For example, 3D design and product development solutions from SOLIDWORKS help engineers conceptualize, create, validate, communicate, manage, and transform ideas into product designs.

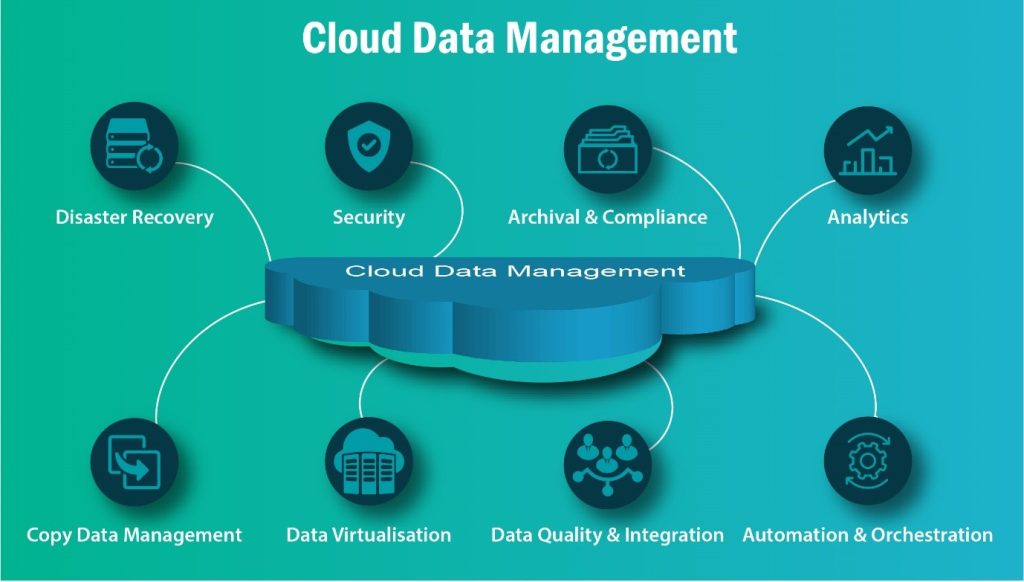

8. Cloud-based data management

Cloud-based platforms are changing the way data is stored and accessed. By migrating data to the cloud, engineering organizations can centralize their data and provide remote access to critical information.

The Snowflake Data Cloud is purpose-built to help companies pursue an aggressive data modernization strategy. Encompassing cloud-built data warehousing, cloud data lake, collaboration, data science, data engineering, applications, and a data marketplace across one or multiple clouds.

9. VR building simulations

Virtual reality (VR) simulations are powerful tools for architectural visualization and design validation. Architects and engineers use VR simulations to visualize building designs and identify flaws before construction begins. VR technology improves decision-making and reduces costly revisions.

For example, Prospect from IrisVR will read 3D files and send them into an immersive, navigable virtual reality environment in one click. This empowers engineering teams to make decisions with speed and confidence.

10. AI-powered generative design

Generative design uses artificial intelligence algorithms to come up with optimized solutions based on user-defined constraints and objectives. This promotes innovation and empowers engineers to explore a range of design alternatives.

For example, with Autodesk Fusion, you can quickly analyze design alternatives using AI-powered, generative design to generate thousands of manufacturing-ready solutions. It helps streamline the design process, reduce costs, and improve the overall quality and performance of the final product.

Engineering Software & Technology Clicks Better With Whatfix

Digital transformation is challenging, costly, resource-intensive, and has lengthy implementation and migration cycles. To complicate matters, all digitalization projects are different.

Accelerate your engineering digital transformation by enabling your technology end-users (internal staff and customers) with contextual in-app guidance and real-time support with Whatfix’s digital adoption platform (DAP).

Whatfix provides engineering teams with a no-code content editor (Whatfix Studio) to create in-app assistance that contextually guides end-users on complex processes and digital experiences, enabling them to utilize digital platforms correctly and drive business outcomes.

With Whatfix, you can enable your end-users with contextual, guided, and self-service experiences to help them drive value from digital investments and maximize their productivity. It also actively works to identify areas of end-user friction to optimize user experiences and build user-friendly digital solutions continuously.

This makes it easier to adjust software training and adoption strategies. All to empower engineering employees and customers to maximize the value of digital tools and manage operations with ease.

Ready to learn more? Request a demo to see how engineering software clicks better with Whatfix now!