What Is the Plan-Do-Check-Act (PDCA) Cycle? +Examples

- Published:

- Updated: July 25, 2024

Process improvement is a continuous journey, not a destination.

In pursuing a more efficient and effective business strategy, organizations must overcome hurdles like resistance to change, project delays, change fatigue, data literacy challenges, skill gaps, and evolving customer needs. These obstacles can make successful change management feel like an uphill battle.

However, proven techniques empower businesses to navigate these change barriers. One such method is the PDCA cycle, a robust framework that enables continuous process improvement.

In this article, we’ll explore the PDCA cycle, its phases and applications, and examples of companies implementing it,

What Is the PDCA Cycle?

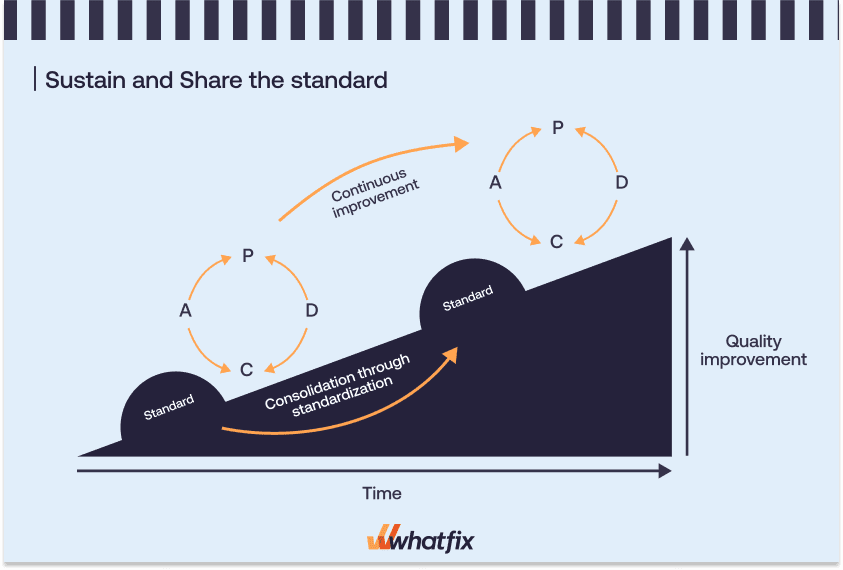

The Plan-Do-Check-Act (PDCA) cycle is a four-step improvement and problem-solving method designed to continuously enhance business processes. It’s the foundation of continuous improvement (or kaizen) and follows the scientific method of proposing a change, implementing it, measuring the impact, and then taking appropriate action.

Organizational leaders set a target to improve on benchmark performance (plan), and teams implement change to improve performance (do). Teams then measure this change’s impact on performance (check) and standardize it into their process (act).

The History of the PDCA Cycle

Also known as the Shewhart Cycle, the Deming Cycle, and the Deming Wheel, the PDCA Cycle was pioneered by the influential American physicist and management consultant Dr. William Edwards Deming in the 1950s.

Deming’s approach revolutionized process improvement by introducing a systematic method for planning, implementing, checking, and acting on changes. This technique was pivotal in the U.S. during World War II, enhancing production processes under pressure and ensuring innovations were consistently aligned with initial plans.

The Four Phases of the PDCA Cycle

The PDCA cycle includes four stages:

- Plan: Determine goals, identify needed changes, and benchmark current performance.

- Do: Implement the change.

- Check: Analyze the impact of the change.

- Act: Standardize the change into your process – or start the cycle again.

The four steps of the PDCA cycle form a closed loop, allowing companies to evaluate all quality control processes from the start. Let’s break down the four phases of the cycle:

1. Plan

In the planning phase, change leaders focus on identifying current pain points and opportunities for improvement and proposing solutions to tackle these issues. This involves creating hypotheses about the underlying problems, benchmarking current performance, and setting a target to improve on this performance.

A common challenge during this phase is ensuring that the proposed changes align with the organization’s overall business objectives. With this alignment, solutions can achieve the core issues.

To address this, developing a detailed project implementation plan is crucial. This plan should outline the proposed changes and how they support the organization’s goals. Regular reviews with key stakeholders help ensure everyone is on the same page and make necessary adjustments to ensure the changes are both relevant and beneficial.

To better understand, consider a customer support team facing high time-to-resolution times for service tickets. Let’s apply the PDCA cycle to see how it can help improve processes, starting with “plan”.

Plan Example

The customer support manager notices an uptick in client complaints regarding slow response times. In response, the objective is set to slash the average ticket resolution time by 20% within the next quarter. To kick off, the manager collects and analyzes current resolution statistics, pinpoints delays, and gathers input from the team on ground-level challenges.

Key steps in the planning phase include:

- Defining the problem: Long resolution times are diminishing customer satisfaction.

- Setting objectives: Aim to cut the average resolution time by 20% in three months.

- Analyzing data: Examine existing resolution times, identify patterns in delays, and pinpoint underlying issues.

- Developing a plan: Introduce new strategies such as prioritized ticketing, targeted training for team members, and optimized use of existing resources.

2. Do

The “Do” stage is all about execution and change implementation. It involves three key steps: training team members to adopt the change and bridge any skills gaps, implementing the proposed changes, and documenting the process for future reference.

A major challenge during this phase is ensuring that the team is adequately prepared and that the implementation goes smoothly. With proper training and documentation, the process can avoid major setbacks.

To overcome this, focus on thorough training sessions addressing potential skill gaps and ensure the implementation process is thoroughly documented. Running a pilot test during this phase can help determine if the proposed changes produce the desired outcomes.

Let’s return to our customer support manager who planned to introduce new strategies to overcome high resolution times. Here is the steps involved in the “do” phase:

Do Example

With a plan in place, the customer support team initiates a pilot program to address the identified issues. This includes deploying a new ticketing system that prioritizes urgent issues and providing targeted training sessions that focus on efficient problem-solving.

Key steps in the do phase include:

- Implementing solutions: Roll out the new ticketing system and conduct training sessions.

- Monitoring closely: Keep a close watch on the new processes to ensure they are followed correctly.

- Documenting everything: Record changes made, challenges faced, and any unexpected observations.

3. Check

The check phase is essential for evaluating the success of your efforts and usually happens at least twice per project. First, you analyze the results of your pilot test, comparing them against the criteria established in the planning stage to determine if the changes were successful. This involves a comprehensive review to identify both successes and opportunities for improvement.

A challenge here can be accurately measuring the outcomes and determining what worked and what didn’t. This can be tricky if the criteria for success are not clearly defined in the beginning.

To tackle this, ensure that the success criteria are specific and measurable. During the check phase, involve the team reviewing the outcomes to gain various perspectives. This collaborative approach helps accurately identify failures and successes, allowing you to make necessary adjustments.

Returning to our customer support example, here are the steps in the “check” phase:

Check Example

After implementing the changes, the manager reviews the new average resolution times and gathers feedback from both customers and support staff. This phase focuses on measuring the impact of the changes against the set objectives and identifying any areas for further improvement.

Key steps in the check phase include:

- Evaluating results: Compare the new data with the old to see if the resolution times have improved.

- Soliciting feedback: Get input from staff and customers about their experiences with the new processes.

- Identifying discrepancies: Look for any gaps between expected outcomes and actual results.

4. Act

The final step in the PDCA cycle is taking corrective action and adjusting to implement the improvement project on a larger scale. This phase solidifies the changes made and sets the stage for the future.

After the final stage, start the process again. It doesn’t matter if your change led to improvements, as processes can constantly be improved. The PDCA should be utilized continuously to optimize and streamline processes to maximize efficiency and production.

One challenge in this phase is ensuring that the changes are effectively integrated into the organization without causing disruptions, as scaling up can bring new obstacles that weren’t apparent during the pilot phase.

To address this, focus on clear communication and training to ensure everyone understands the new processes. Treat the new implementation as a baseline for future improvements, continuously monitoring and refining the process as needed.

To close out our customer support example, here is the steps involved in the “act” phase:

Act Example

Based on the insights gained from the ‘Check’ phase, the manager makes necessary adjustments to optimize the process further. This could involve additional training, tweaking the ticketing system, or even revising the goals if they seem too ambitious or too modest.

Key steps in the act phase include:

- Making adjustments: Refine the processes based on feedback and results.

- Standardizing successful practices: Implement the proven effective methods across the board.

- Setting the stage for continuous improvement: Plan for ongoing reviews and updates to maintain and enhance the resolution process.

When to Use the PDCA Cycle

With over 70% of large-scale change projects failing, knowing when and how to use the PDCA cycle to improve processes is vital to continued growth and organizational success. Here are six use cases for utilizing the PDCA cycle to drive change adoption and improve processes successfully:

Business process optimization: The PDCA cycle is a go-to for either introducing a new process or tweaking an existing one. It allows you to methodically plan, execute, and refine processes. As you implement changes and gather feedback, you can make informed adjustments that enhance efficiency and performance.

Defining and documenting Workflows: When tackling manual or repetitive tasks, the PDCA cycle proves invaluable. It helps clearly outline and document processes, which streamlines tasks and boosts efficiency. By revisiting and refining these processes regularly, you ensure they remain effective and up-to-date.

Making data-driven decisions: Leverage the PDCA cycle to base your decisions on solid data. Start with a hypothesis or initial plan, put it into action, evaluate the results, and then tweak your strategy based on the insights you gather. This approach ensures your decisions are always backed by the latest data.

Implementing change: When it’s time for change, the PDCA cycle allows you to pilot your ideas on a small scale first. This way, you can spot potential issues before they become major, making it easier to manage changes and integrate them smoothly across your organization.

Migrating to new systems: Switching to a new system or workflow can be daunting. The PDCA cycle helps by providing a clear roadmap for the transition. Plan your steps, execute them, check the outcomes, and make necessary adjustments. This structured approach reduces downtime and integrates new systems more fluidly.

Launching a new product: Use the PDCA cycle to fine-tune your product launch. It’s particularly useful for experimental products, allowing you to test, gather feedback, and improve before a full-scale launch. This iterative process increases the chances that your new product will meet market needs and gain traction quickly.

Examples of Companies Using the PDCA Cycle

The PDCA cycle has proven to be an effective tool for continuous improvement across various industries. Companies worldwide have successfully implemented this methodology to enhance their processes, reduce waste, and improve overall efficiency.

Let’s look at some examples of companies that have successfully implemented the PDCA cycle:

1. Nike

Nike has long been known for its innovative approach to manufacturing, but it also faced significant challenges with poor work conditions.

Nike adopted the PDCA cycle to address these issues, empowering its employees, partners, and customers. The company offered incentives to factories that improved working conditions and introduced a scoring system to assess the performance of its production facilities.

By committing to continuous improvement and lean methodologies, Nike enhanced working conditions, eliminated waste, and employed value-oriented managers. This dedication to improvement played a significant role in Nike’s impressive growth, doubling its size from $100 billion in 2015 to over $200 billion in 2021.

|

PHASE |

DESCRIPTION |

| Plan | Nike identified poor working conditions as a key issue and proposed solutions to address them. The company developed incentives for factories to improve these conditions and created a scoring system to evaluate performance. |

| Do | Implementation involved rolling out the incentives and scoring system across Nike’s production facilities. Nike also trained managers and employees to adopt lean methodologies. |

| Check | Nike continuously monitored the performance of its factories using the scoring system, assessing the effectiveness of the incentives and identifying areas for further improvement. |

| Act | Based on the evaluations, Nike made necessary adjustments to its processes, reinforcing successful strategies and addressing any shortcomings. This ensured ongoing enhancement of working conditions and operational efficiency. |

2. The Mayo Clinic

The Mayo Clinic, a renowned non-profit hospital, aimed to enhance patient care by reducing wait times and improving treatment quality. Combining Kaizen with the PDCA cycle, the clinic focused on refining specific treatments, managing patient records, and improving waiting room efficiency. As a result, the median cycle time for candidacy testing dropped from 7.3 hours to 3 hours, and the total inventory stock was reduced by 31%.

|

PHASE |

DESCRIPTION |

| Plan | The Mayo Clinic identified long patient wait times and inefficiencies in treatment processes as critical issues. The hospital developed a plan to address these problems by implementing Kaizen and the PDCA cycle to streamline operations. |

| Do | The clinic initiated the improvement process by refining specific treatments, managing patient records more efficiently, and optimizing waiting room times. Staff were trained in the new procedures and lean methodologies. |

| Check | The Mayo Clinic monitored the impact of the changes by measuring patient wait times and tracking inventory levels. This helped determine the effectiveness of the implemented solutions. |

| Act | Based on the data, the clinic made adjustments to further reduce wait times and improve patient care. Successful strategies were reinforced and shortcomings were addressed, ensuring continuous improvement. |

3. Nestlé

Nestlé, a global leader in the food and beverage industry, aimed to reduce waste by adopting lean methodologies. The company implemented the Kaizen method to promote a culture of continuous improvement across all levels and used the PDCA cycle to provide a detailed framework and enhance accountability.

Nestlé Waters utilized techniques like Value Stream Mapping (VSM) to visualize the flow of materials and information necessary to deliver finished products to consumers. This approach boosted the efficiency of new bottling plants.

Nestlé’s commitment to continuous improvement through the PDCA cycle and lean methodologies reduced waste. They significantly increased the efficiency of its bottling operations, demonstrating the power of a structured approach to process optimization.

|

PHASE |

DESCRIPTION |

| Plan | Nestlé identified waste reduction as a key objective and developed a plan to implement lean methodologies. The company introduced Kaizen to foster continuous improvement and employed Value Stream Mapping to understand material and information flows. |

| Do | The improvement process was initiated by training employees in Kaizen and lean practices. Nestlé Waters used VSM to optimize operations in new bottling plants, focusing on efficient material and information flow. |

| Check | Nestlé monitored the effectiveness of the implemented changes by assessing the efficiency of the bottling plants and tracking waste reduction. Regular evaluations helped identify areas for further improvement. |

| Act | Based on the gathered insights, Nestlé made necessary adjustments to its processes, reinforcing successful strategies and addressing any issues. Doing so ensured ongoing improvements in efficiency and waste reduction. |

4. Toyota

Toyota, a pioneer in lean manufacturing, has long been committed to continuous improvement. The company uses the PDCA cycle to enhance its production processes, ensuring quality and efficiency at every stage.

Toyota implemented the PDCA cycle by identifying production inefficiencies and developing a plan to address them. Toyota has maintained its reputation for high-quality manufacturing and operational excellence by continuously monitoring and refining its processes.

PHASE | DESCRIPTION |

Plan | Toyota identified inefficiencies in its production processes and developed a plan to address them. This included setting specific targets for quality and efficiency improvements. |

Do | The company implemented changes by training employees in lean methodologies and adjusting production processes. Some key actions included standardizing work procedures and integrating advanced technologies. |

Check | Toyota regularly monitored production metrics to evaluate the effectiveness of the changes. This involved detailed analysis of quality control data and production efficiency. |

Act | Based on the data, Toyota made necessary adjustments to its processes. Successful strategies were reinforced, and any issues were promptly addressed to ensure continuous improvement. |

5. Starbucks

Starbucks, the global coffeehouse chain, has effectively used the PDCA cycle to enhance customer experience and streamline operations. Faced with challenges like long wait times and inconsistent product quality, Starbucks turned to the PDCA cycle for continuous improvement.

Starbucks’ application of the PDCA cycle has been crucial in maintaining its high standards of service and product quality, demonstrating the effectiveness of a structured approach to continuous improvement in the retail industry.

|

PHASE |

DESCRIPTION |

| Plan | Starbucks identified long wait times and inconsistent product quality as fundamental issues. They developed a plan to address these problems by optimizing workflows and enhancing service quality. |

| Do | The company implemented changes by training baristas on new procedures, introducing more efficient equipment, and reorganizing store layouts to improve customer flow. |

| Check | Starbucks continuously monitored customer feedback and operational metrics, such as average wait times and order accuracy, to assess the effectiveness of the changes. |

| Act | Based on the feedback and data collected, Starbucks made necessary adjustments to its processes, like refining training programs and making further layout changes. Successful strategies were scaled across stores, ensuring consistent improvements. |

✓ Thank you, the checklist will be sent to your email

PDCA Cycle

FAQs

What are the benefits of the PDCA cycle?

- Achieves successful change, reduces waste, and increases process efficiency.

- Simplifies processes and minimizes errors through repetition, creating standard operating procedures.

- Versatile technique for project management, change management, product development, and quality management.

- Provides visibility into core processes and captures data to prove results.

What are the limitations of the PDCA cycle?

- Requires leadership buy-in and a firm commitment as a continuous process.

- Needs to be carried out repeatedly; one-time use leads to wasted resources.

- Not suitable for time-sensitive projects.

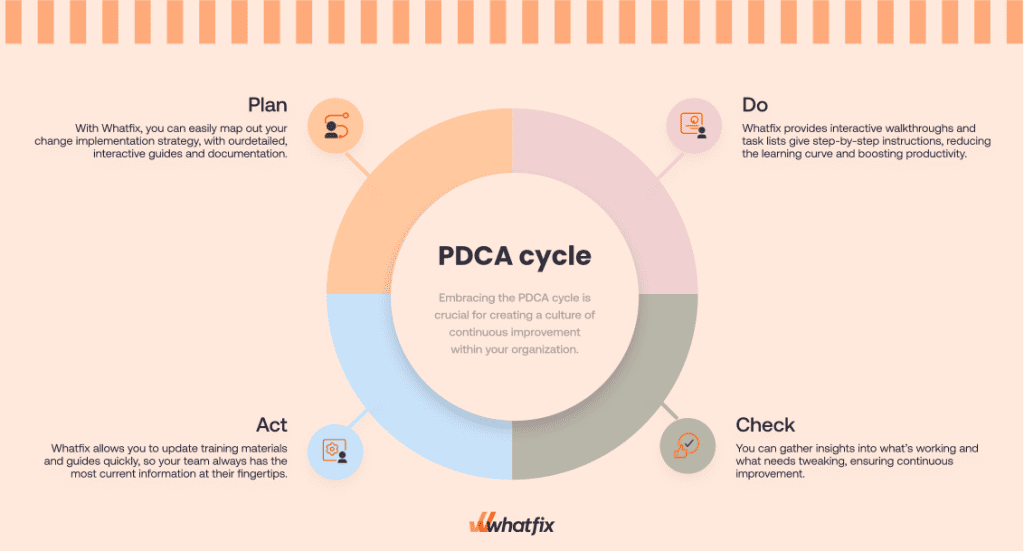

Embracing the PDCA cycle is crucial for creating a culture of continuous improvement within your organization. Regularly updating and refining business processes ensures your company runs efficiently and keeps operating costs low.

When rolling out changes, focusing on effectively adopting new processes is vital. This is where Whatfix comes through, supporting each phase of the PDCA cycle seamlessly:

- Plan: With Whatfix, you can easily map out your change implementation strategy. Our tools help you create detailed, interactive guides and documentation, making sure everyone understands the goals, processes, and expected outcomes of the change initiative.

- Do: As you implement changes, Whatfix provides in-app guidance and real-time support to help your employees transition smoothly. Interactive walkthroughs and task lists give step-by-step instructions, reducing the learning curve and boosting productivity.

- Check: Our analytics and feedback tools let you monitor the effectiveness of the changes. By tracking user engagement and performance, you can gather insights into what’s working and what needs tweaking, ensuring continuous improvement.

- Act: You can fine-tune your processes based on the feedback and data collected. Whatfix’s flexible platform allows you to update training materials and guides quickly, so your team always has the most current information at their fingertips.

With Whatfix, you can implement change without losing productivity or overloading your IT support teams. Our in-app guidance empowers your workforce to onboard, train, and support themselves with product tours, interactive walkthroughs, task lists, tooltips, and self-help knowledge bases.

Learn more about how What can help you integrate the PDCA cycle into your continuous improvement efforts today.

Thank you for subscribing!

Thank you for subscribing!