Operations and maintenance (O&M) manuals are the go-to resource for keeping facilities, equipment, and systems running smoothly. From guiding maintenance teams through troubleshooting to helping facility managers plan long-term upkeep, O&M manuals are essential technical documentation in an organization’s facilities and operations toolkit.

O&M manuals provide clear, detailed end-user documentation and step-by-step instructions to ensure systems and equipment are operated safely and maintained properly. They’re not just for internal teams—contractors, vendors, and even customers rely on these manuals to handle equipment and processes confidently. Whether extending the life of expensive assets, reducing downtime, or creating safer work environments, these manuals play a critical role in day-to-day operations.

But what makes an effective O&M manual? It’s not just about throwing together a list of instructions. The best manuals are well-structured, easy to navigate, and packed with actionable insights tailored to their users’ needs. They blend technical precision and practical usability, designed to simplify complex processes and keep teams on track.

In this article, we’ll discuss what O&M manuals are, their key components, and how they benefit organizations. We’ll also walk you through the steps to create one, offer examples to get you started, and share how a digital adoption platform like Whatfix can bring your O&M manuals to life with in-app guidance.

What Is an Operations and Maintenance (O&M) Manual?

An operations and maintenance (O&M) manual is a type of user guide that outlines how to run, operate, maintain, and troubleshoot a piece of equipment or system, typically in a facility. O&M manuals provide instructions for routine tasks, offer guidance for troubleshooting issues, and support consistency in operations across your organization. O&M manuals keep things running smoothly and are exceptionally vital for complex systems or facilities where proper maintenance is critical.

Types of Operations and Maintenance Manuals

Different organizations need different types of O&M manuals. Here are some of the common ones.

- Product installation and maintenance manuals: These O&M guides help users set up and maintain specific products. They’re common for appliances, tech devices, and IT hardware. A sound installation manual leads to proper setup, and a maintenance guide extends the product’s life.

- Backup and recovery manuals: Data is a valuable resource in every industry. Backup and recovery manuals outline procedures for protecting and restoring information. They’re essential for IT departments and data-centric businesses.

- Software administration manuals: These guides help IT staff manage software systems. They cover everything from installation to troubleshooting. Clear admin manuals are an essential piece of the puzzle for smooth software operations and provide step-by-step instructions for IT administrators.

- HR manuals: HR manuals outline company policies and procedures, covering hiring processes and employee conduct guidelines. A well-crafted HR or training manual is a guide to workplace behavior and expectations.

- Customer care and support manuals: These guides help customer service teams provide consistent, high-quality support. They often include troubleshooting steps and company policies. Good support manuals lead to better customer experiences.

- Procurement and manufacturing guides: These manuals detail processes for acquiring materials and producing goods. They provide standard operating procedures (SOPs) that bring consistency in supply chain and production operations, and clear procurement guides can also lead to cost savings.

- Emergency and safety procedures: Safety is at the core of any workplace. These manuals outline steps for handling emergencies. This could be different from workplace to workplace. For example, teams working in an office building need a fire evacuation plan. Well-designed safety manuals can save lives.

- Industrial aid manuals: Industrial aid manuals are user guides for workers in industrial settings. They might cover machine operation or safety procedures. Industrial manuals boost productivity and safety, allowing well-prepared employees to do their best work.

- Quick reference manuals and work assistance guides: Quick reference guides are concise documents that answer common questions quickly. They’re handy for new employees or customers. They can also give long-time employees a quick refresher on specific tasks. Good quick reference guides save time and reduce errors.

Components of an O&M Manual

A well-crafted O&M manual is essential for streamlining asset management and improving operational efficiency. Below, we break down the key components of an O&M manual and provide practical examples for each section to make your manual robust and actionable.

1. General company overview

This section introduces your company, offering insights into its history, structure, and key departments. A clear overview establishes context and helps employees and contractors understand how their responsibilities align with organizational goals.

Key elements to include in this section:

- Company history, mission, and vision statements

- Organizational charts showing department structures and reporting lines

- Overview of the company’s operations and key facilities

2. Maintenance procedures

This section focuses on strategies and steps for effectively maintaining assets. It should include preventive and corrective maintenance programs that help minimize downtime and extend equipment life. Clear documentation here ensures consistency and reduces errors in maintenance workflows.

Key elements to include in this section:

- Preventive maintenance schedules, tasks, and frequencies

- Troubleshooting guides for common equipment failures

- Corrective maintenance procedures with step-by-step instructions

3. Emergency procedures

Emergencies can disrupt operations and jeopardize safety. This section provides clear, actionable steps for managing crises to minimize risks and ensure worker safety. Include contact information and escalation protocols for quick decision-making during critical situations.

Key elements to include in this section:

- Contact list of key personnel, emergency responders, and contractors

- Evacuation plans, including floor plans with marked exits

- Communication protocols for alerting teams and external agencies

4. Facility details and equipment placement maps

Facility details and maps provide a comprehensive view of the site’s layout and the location of critical assets. This information is invaluable for maintenance teams, third-party contractors, and long-term planning.

Key elements to include in this section:

- Floor plans with equipment placement and utility lines marked

- Site surveys detailing infrastructure specifications and materials

- Equipment registries with details like manufacturer, model number, and location

5. Operating procedures

A detailed section of operating procedures ensures consistency and efficiency in daily operations. It acts as a reference guide for teams, promoting adherence to standard practices and reducing the margin for errors.

Key elements to include in this section:

- Step-by-step instructions for standard operating procedures (SOPs)

- Safety protocols specific to operating certain machinery or systems

- Performance benchmarks and guidelines for optimizing workflows

6. Other components

Requirements for an O&M manual will change, depending on the industry and product’s contextual needs or differences.

Additional sections might include:

- Warranty certificates

- Design principles and drawings

- Disposal guidelines

Benefits of O&M Manuals

O&M manuals offer benefits for your organization at large and individual employees. Here’s what you can expect.

- Process governance: O&M manuals keep everyone on the same page, so they follow the proper procedures. This ensures process governance that leads to consistent quality and efficiency. It’s essential in manufacturing and service industries, where small mistakes can lead to more significant issues.

- Prolonged asset lifecycle: Maintenance extends the life of equipment and facilities. O&M manuals guide the proactively needed maintenance your employees need, helping your business save time and money.

- Reduces downtime and maintenance costs: When everyone knows the procedures, they can resolve issues faster. This reduces costly downtime. It also makes everyone more efficient. Clear expectations create better business outcomes.

- Supports safety: Safety procedures protect workers and visitors on site, preventing accidents and associated costs. They also help companies comply with regulations that some industries, such as government and healthcare, require.

O&M Manual Template

Start creating your operations and maintenance manual with our free template. Complete the form below, copy the template, and customize based on your company’s branding and your O&M needs:

✓ Thank you, the checklist will be sent to your email

How to Create an Operations and Maintenance Manual

Creating a practical and effective O&M manual requires thoughtful planning and execution. Follow these steps to build a manual that supports your organization’s needs while empowering employees with accessible, actionable information.

1. Conduct research

Gather all relevant information, including equipment specifications, industry standards, safety protocols, and company policies. Proper research lays the foundation for a comprehensive O&M manual that can effectively guide teams.

2. Assemble a team and collaborate with stakeholders

Involve employees from various departments, including maintenance personnel, managers, and compliance officers. Their hands-on knowledge and operational insights will make your manual practical and well-rounded.

3. Use digital tools to create your manuals

Digital platforms streamline manual creation and distribution. They make updates more manageable and provide everyone access to the latest information. This is especially important in an environment where more teams are distributed across locations.

![]()

4. Design a template

Create a user-friendly, structured template using headers, subheaders, and bullet points. A clear format improves readability and ensures consistency across sections.

5. Create and review O&M content

Write clear, concise instructions tailored to your organization’s processes. Avoid jargon and use visuals where possible to clarify complex tasks. Review content thoroughly to ensure it’s accurate and actionable.

6. Collect feedback and implement changes

Get input from the employees who are using the manual. Based on their end-user feedback, consider changes. This process should be ongoing as you develop new workflows and retire others.

Whatfix allows you to create in-app surveys to collect feedback inside applications. These can be open or close-ended questions, surveys, questionnaires, interviews, and focus groups that are designed around different parts of the experience from ease of use to effectiveness.

7. Monitoring usage and regularly updating the manual

Track how people use the operations and maintenance manual in their daily work. Update it regularly to reflect changes in your operations. Regular reviews keep the manual relevant and valuable.

With an application analytics platform like Whatfix Product Analytics, leaders can understand how employees interact with O&M manuals. They can also track key actions using a no-code tool to set up custom user events.

Examples of O&M Manuals

Creating an O&M manual can seem daunting, but looking at examples from similar industries can help provide clarity and inspiration.

Here are some examples of different types of O&M manuals that you can model your own after.

1. Plant operations manual

A plant operations manual provides the blueprint for maintaining and operating a manufacturing or processing plant. It typically includes sections on equipment operation, safety protocols, maintenance schedules, and troubleshooting guides. These manuals ensure that all equipment and machinery are running optimally, helping minimize downtime and extend asset lifecycles.

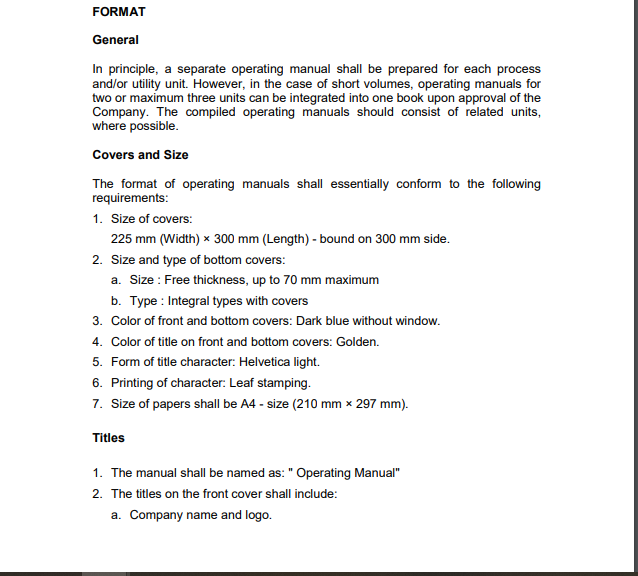

KLM Technology Group’s Plant Operations Manual is a comprehensive resource for managing plant operations. It includes detailed sections on equipment maintenance, operational safety, troubleshooting guides, and emergency procedures.

What makes this O&M manual good:

- Includes detailed emergency response plans to minimize downtime

- Offers step-by-step troubleshooting guides for quick issue resolution

- Contains clear maintenance schedules to ensure optimal equipment performance

2. HVAC maintenance manual

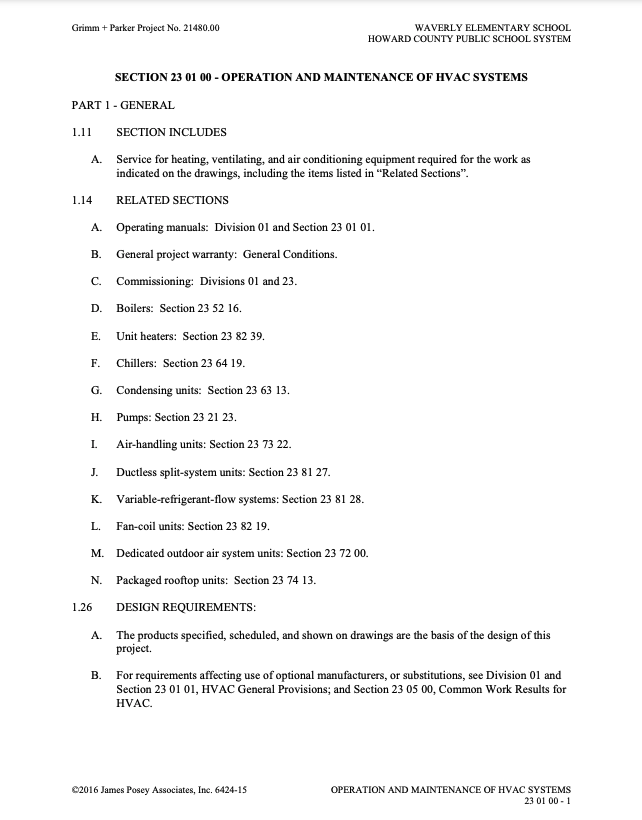

HVAC maintenance manuals focus on the upkeep of heating, ventilation, and air conditioning systems. These manuals typically include preventative maintenance schedules, troubleshooting steps, energy efficiency tips, and safety protocols. They help ensure that HVAC systems run efficiently and extend the life of critical climate control equipment.

The Waverly Elementary School and Howard County Public School System’s HVAC O&M Manual is an excellent example of an HVAC maintenance guide. It covers all aspects of maintaining HVAC equipment, from basic cleaning to complex system diagnostics.

What makes this O&M manual good:

- Provides clear diagnostics for identifying HVAC issues

- Includes maintenance routines for energy efficiency optimization

- Features detailed cleaning and replacement protocols for critical components

3. Fire protection system operating manual

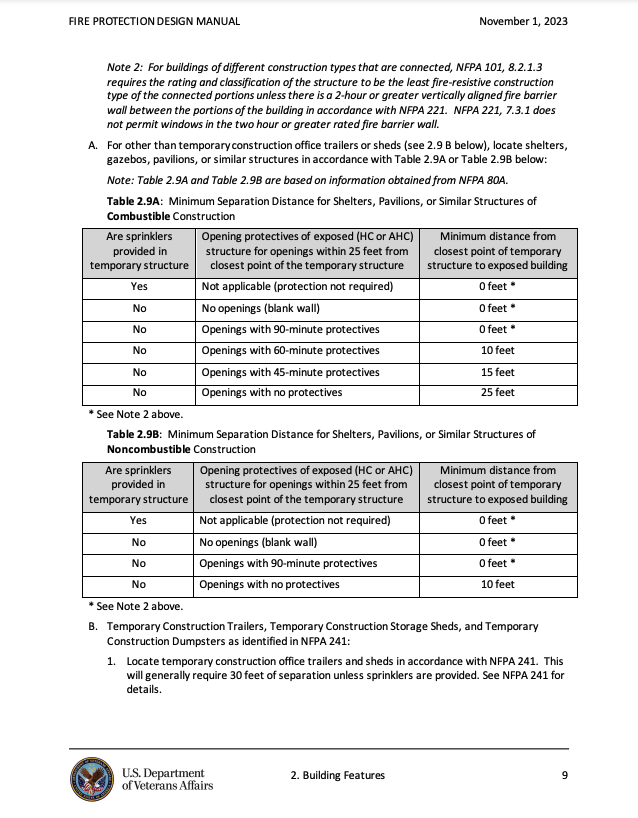

Fire protection system manuals offer detailed guidance on operating, maintaining, and inspecting fire safety systems, such as alarms, extinguishers, sprinklers, and fire suppression systems. These manuals include maintenance schedules, testing procedures, and emergency response protocols, ensuring that critical fire safety equipment remains fully functional.

The US Department of Veterans Affairs (VA) provides a Fire Protection Design Manual that details the procedures for maintaining fire safety equipment across various facilities. This manual includes inspection protocols, emergency steps, and system testing schedules.

What makes this O&M manual good:

- Lists testing schedules to ensure fire systems remain fully operational

- Outlines emergency protocols tailored to various fire scenarios

- Includes compliance standards for regulatory adherence

4. Systems operations manual

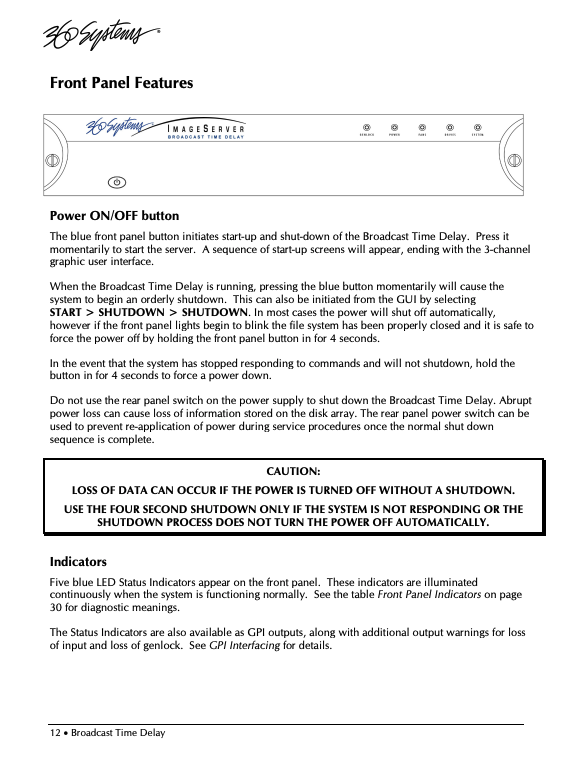

A systems operations manual provides essential details on maintaining and troubleshooting the various systems that support facility operations, including electrical systems, IT infrastructure, and critical backup systems. These manuals help ensure that all systems run efficiently and that maintenance is performed promptly to avoid costly disruptions.

360 System’s Operations Manual outlines electrical and IT system maintenance and operational procedures. It covers everything from preventive maintenance to emergency protocols, ensuring systems are always running smoothly.

What makes this O&M manual good:

- Features specific guidelines for electrical system upkeep and troubleshooting

- Provides comprehensive steps for maintaining IT infrastructure

- Includes preventative protocols to avoid system downtime

5. Nursing home operations manual

A nursing home operations manual guides the upkeep of equipment and systems within a nursing facility. It includes maintenance schedules for medical equipment, HVAC systems, and emergency backup systems, ensuring everything runs smoothly for resident care.

HC Pro Marketplace’s Comprehensive Manual for Nursing Home Administration provides a detailed framework for managing nursing home operations. It includes sections on equipment maintenance, safety protocols, and compliance with healthcare regulations.

What makes this O&M manual good:

- Focuses on maintaining life-saving medical equipment and systems

- Includes safety protocols for resident and staff well-being

- Offers compliance checklists for regulatory adherence

6. School operations manual

A school operations manual outlines the maintenance and operational procedures for building systems like HVAC, lighting, and security. It also includes safety protocols and maintenance schedules for school-owned equipment.

The Swiss Resource Center and Consultancies for Development’s Operation and Maintenance Manual for Public Schools offers a detailed guide on maintaining school infrastructure. It includes checklists for facility upkeep, waste management, and resource allocation.

What makes this O&M manual good:

- Features maintenance schedules for critical building systems like lighting

- Includes waste management plans to enhance sustainability efforts

- Provides resource allocation tips for maintaining school infrastructure efficiently

7. Backup and recovery manuals

Backup and recovery manuals guide the process of protecting and restoring critical data. They include procedures for creating backups, identifying potential risks, and steps for data recovery. They also cover specific software or tools used.

The Operations and Maintenance Manual from the Centers for Medicare & Medicaid Services (CMS) provides detailed instructions on maintaining backup and recovery systems for sensitive healthcare data. It emphasizes security protocols and recovery plans to minimize system downtime.

What makes this O&M manual good:

- Outlines step-by-step recovery plans to minimize disruptions

- Offers risk assessment strategies tailored to sensitive healthcare data

- Details security protocols to ensure data protection compliance

8. Product safety manuals

A product safety manual covers a specific product’s safe use and handling. It includes information on potential hazards, and safety precautions, and offers instructions for assembly, operation, and maintenance.

The Association of Equipment Manufacturers’ Compact Excavator Safety Manual offers comprehensive guidelines for the safe operation of compact excavators. It provides detailed safety protocols, maintenance tips, and troubleshooting instructions.

What makes the O&M manual good:

- Focuses on hazard identification and mitigation for user safety

- Includes troubleshooting tips for common equipment issues

- Provides maintenance steps to ensure longevity and functionality

Operations and Maintenance Manuals Click Better with Whatfix

Creating an O&M manual is more than a requirement—it’s a foundational step toward efficient operations, longer asset lifecycles, and a safer work environment. A well-crafted O&M manual empowers teams by providing clear, accessible guidance, from daily operating procedures to emergency protocols.

But building and maintaining a practical manual isn’t a one-time effort—it requires collaboration, ongoing updates, and seamless accessibility to ensure it remains relevant and actionable. That’s where technology becomes a powerful ally.

With Whatfix, you can take your O&M manual to the next level by transforming static documents into dynamic, in-app experiences. Empower your employees with:

- On-demand access to SOPs, policies, and resources through a centralized, searchable in-app help center.

- Guided workflows and contextual task assistance to simplify complex procedures and reduce errors.

- Real-time analytics to track usage, identify gaps, and continuously improve the accessibility and usability of your manual.

- User feedback tools to ensure your manual evolves with your organization’s needs.

Whatfix ensures your teams have the right information at the right time, all within the flow of their work. By making your O&M manual more accessible, actionable, and engaging, you can help your organization reduce downtime, cut maintenance costs, and keep employees safe and confident.

Take your operations and maintenance manuals to the next level by partnering with Whatfix to streamline creation, updates, and employee training effortlessly. Request a demo today!