13 Common Procurement Risks & How To Minimize Them

- Published: November 3, 2022

- Updated: December 21, 2023

Risks can unfold at any time without warning.

The COVID-19 pandemic is a prime example of how sudden change can severely impact businesses. A core business function caught in the middle of these tidal waves of change is procurement.

Procurement is the act of purchasing the goods and services that businesses need daily. This function has unique expertise in supply chains, cash flow, and relationships with vendors and suppliers.

Many businesses looked to procurement knowledge as assets for strategically guiding them through market disruption. In fact, 86% of leaders believe that procurement influenced their company’s post-pandemic recovery.

All this starts with a procurement process equipped to overcome and manage different forms of risk. Let’s dive into what that means for your business.

Top 13 Procurement Risks for 2024

- Inaccurate internal needs analysis

- Poor vendor sourcing

- Ineffective supplier and vendor onboarding

- Inadequate vendor management

- Price instability

- Resistance to digitalization leading to poor e-procurement adoption

- Supply chain disruptions

- Manual procurement processes

- Inaccurate forecasting

- Compliance management

- Budget overspend

- Talent shortage

- Inefficient contract management

What Are Procurement Risks?

Procurement risks are different scenarios in which businesses could potentially fail to purchase an essential product, resource, or service. By not properly identifying procurement risks beforehand, companies are more prone to dealing with unreliable suppliers, not meeting deadlines, and stretching out their budgets to cover avoidable costs.

A report by McKinsey outlines three sources of procurement risk:

- Product shortage risk: When products can’t be purchased in the necessary amount to meet customer or client needs.

- Supplier risk: When companies work with suppliers that negatively impact the delivery of their product to end users.

- Inflation risk: When the price of available products suddenly increases.

Importance of Procurement Risk Management

Procurement risk management isn’t nice-to-have — it’s necessary for your bottom line.

Businesses must consistently monitor risk factors impacting their current and future procurement. Procurement leaders say companies can generate cost savings of 11-20% with more transparency.

Here are a few other reasons why procurement risk management can help you drive growth and revenue:

- Removes siloes and miscommunication within the organization

- Keeps resource expenditure within a reasonable limit

- Improves relationships with vendors

- Makes customers happy

- Ensures business continuity

13 Common Procurement Risks to Watch

If you’re building a plan to help your business better prevent and predict procurement risks, you need to familiarize yourself with procurement risks that businesses commonly face.

1. Inaccurate internal needs analysis

The internal needs analysis is the first step of the procurement process. It calls for you to take a deep dive into your current performance, budgets, inventory, growth projections, resource levels, economic influences, and more. This analysis gives you a clear idea of exactly what your procurement processes need to meet targets and what you can do to adapt to weaknesses in supply chains and overall markets.

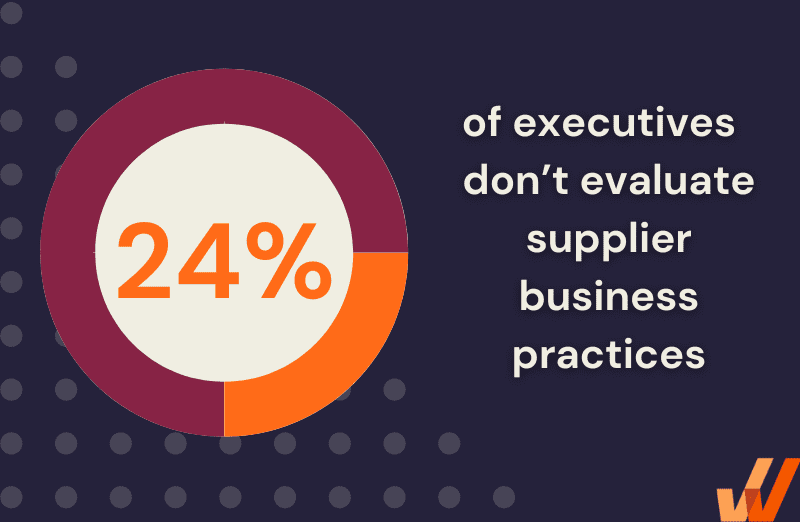

2. Poor vendor sourcing

You depend on your vendors to receive the goods and services you need, but some companies still find it difficult to research their procurement partners. In fact, a survey by Harvard Business Review found that 24% of executives still don’t evaluate supplier business practices properly. An unreliable vendor can impact your entire operations, so it’s important that you have a thorough vendor evaluation process. Many factors go into deciding on a suitable vendor that meets your needs, like:

- The quality of the vendor’s products and supplier relationships

- If the vendor has any financial risks that may lead to a low supply of products

- Regulations and legal compliance with the vendor’s business practices

- Data security of vendor’s internal systems

- How mature and capable the vendor is of bouncing back from market changes

3. Ineffective supplier and vendor onboarding

Communication with suppliers and vendors breaks down easily if they’re not strong from the very beginning. All parties should be brought through an onboarding process to familiarize themselves with the expectations your company will use to measure success.

The vendor onboarding process includes collecting necessary documentation, reviewing standard questions, completing final compliance checks, and reviewing timelines and expected deliverables. With a well-managed onboarding process, you won’t miss out on important paperwork and will likely catch warning signs from unreliable and unethical vendors.

4. Inadequate vendor management

Vendor management involves overseeing communication channels, order management, the status of suppliers, and other data and business metrics that you’ll use to define successful procurement.

The vendor relationship becomes difficult to manage if you manually track milestones and activities with every vendor and supplier. For this reason, 69% of procurement leaders consider digital and analytics solutions more valuable post-pandemic. This allows companies to consistently monitor and analyze opportunities and bottlenecks without the inconvenience of incomplete data across scattered systems.

5. Price instability

Unforeseen pricing changes can greatly undermine your business operations. But there are digital analytics processes that can help. According to McKinsey, companies can take an analytics-heavy approach to make baseline predictions for pricing changes in products. This approach is centered around three steps:

- Take a ‘cleansheet’ approach —in which you analyze a product’s complete cost structure, from raw materials to delivery — to understand how prices may change over time

- Model expected price changes using forecast metrics and analysis from market experts

- Rank the risk of inflation in your vendor and supplier categories

6. Resistance to digitalization leading to poor e-procurement adoption

Many companies are adopting digital solutions to centralize, scale and conduct in-depth spend analysis on procurement processes to avoid risk. However, digitization is not something you can jump on your suppliers and vendors without proper training, onboarding, and an easy-to-use interface.

Julie Niedehoff, an associate professor of supply chain management at Syracuse University, says that “it requires a lot of trust” to get all parties to embrace new technology systems. Vendors and suppliers may not be willing to trust your technology with their data or spend time ramping up on a new tool. This is where it becomes valuable to use digital adoption platforms to accelerate onboarding by removing any guesswork and siloes while using new systems.

JULIE NIEDERHOFF

ASSOCIATE PROFESSOR OF SUPPLY CHAIN MANAGEMENT | SYRACUSE UNIVERSITY

7. Supply chain disruptions

From port congestions to manufacturing delays and labor shortages, supply chains have been interrupted worldwide due to geographic limitations, political pressure, and even extreme weather. One example is how the winter storms cut off food supply chains in Texas in February 2021. This was caused by a flood of panic-buying from millions of impacted Texans, coupled with poor road conditions and no power in manufacturing and warehousing facilities.

Your procurement process should include sitting down with stakeholders to define scenarios that might impact supply chains in the near and long term. From there, you can identify risk-management policies for low-impact and high-impact risks that may be difficult to anticipate.

8. Manual procurement processes

55% of procurement functions typically run on spreadsheets. This form of manual data entry can impact your procurement processes in a few ways:

- Time-consuming to consistently upkeep

- Source of human error

- Can’t centralize all procurement information in a user-friendly layout

- More prone to incomplete and inconsistent data

- Difficult to maintain as operations scale

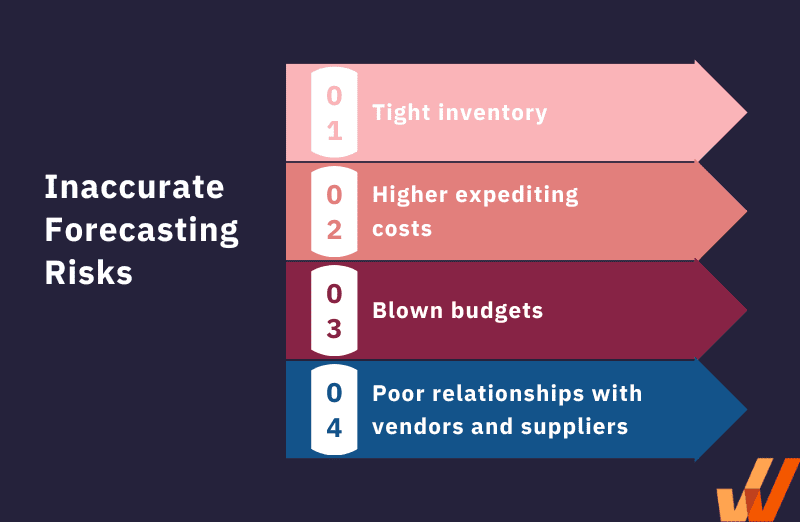

9. Inaccurate forecasting

Procurement forecasting is your ability to predict sales and periods of peak customer demand, and consequently, come up with the right strategies to support those predictions. But when forecasting numbers deviate too much, it restricts your operations and harms your ability to generate revenue.

Inaccurate forecasting introduces risk in the form of tight inventory, higher expediting costs, blown budgets, and poor relationships with vendors and suppliers.

10. Compliance management

Procurement compliance involves formulating processes and policies that guard your cash flow against unauthorized spending, poor ethics, and high-risk partnerships with suppliers and vendors. Procurement compliance standards can include baseline expectations for on-contract spending, supplier performance, discounts, and the time to make payments.

Without compliance management, companies have less protection against poor cash management practices from both internal team members and external partners.

11. Budget overspend

There’s no denying that overspending leads to unreliable procurement from start to finish. It puts your relationship with suppliers and vendors at risk.

There are many points in the procurement process where you can catch red flags in your budget before an order is placed:

- The internal needs analysis

- Vendor and supplier onboarding

- Market forecasting

- Compliance checks

Ultimately, the biggest source of poor spending is when companies fail to plan their needs early, don’t have visibility into existing spending performance and risks, and do not implement policies to avoid off-contract spending.

12. Talent shortage

Talent shortages can stem from a range of social and organizational factors. Some of the most familiar discussions of the 2020s involve how talent is becoming more conscious of their employer’s stance on work flexibility, work-life balance, and environmental, social, and governance (ESG) initiatives.

Phil Fersht, chief analyst at HSF Research, tells Supply Chain Brain that procurement companies aren’t struggling with a talent shortage rather than a shortage of the right talent. First, companies must reevaluate their hiring processes, leadership, and work culture. Next, they should embrace digitization to see how they can offload manual outdated processes from employees so teams can focus on more high-impact work.

13. Inefficient contract management

Contracts are used in some industries to manage risk and maintain profits through index-based pricing. Contracts minimize risk by ensuring procurement practices don’t break the law and are defined by clear KPIs and review processes.

Poor contract management happens when contracts are left unmonitored after it has been signed. Contract management should be a key part of your digitization process so you can automate contract signing and streamline vendor terms and conditions, so they’re easy to find and access.

7 Tips to Minimize Procurement Risks

60% of business leaders say they lack transparency within their procurement functions. This lack of visibility is the biggest reason why many companies fail to detect risks.

Here are five ways you can adopt more organized and transparent procurement practices:

1. Standardize procurement processes

Standardization ensures that every team member goes through the same company-approved steps when conducting procurement processes or communicating with suppliers and vendors.

What does process standardization look like in an end-to-end workflow?

- A defined list of business-critical factors to drive your internal needs analysis

- Vendor and supplier assessment is conducted according to a set guideline

- Teams follow a clear list or policy on vendor documentation and information that needs to be communicated

- Expenditure is brought through a review process that removes ambiguity and is in line with overall budgets

- Performance data is captured into databases in a consistent way

Standardization is harder to maintain if all processes are monitored and tracked manually. By centralizing your strategic procurement playbook into a digital database or portal, your team and external partners have no excuse if they fail to follow through with set guidelines.

2. Automate tedious procurement tasks

Many tasks consume a lot of time but have little to no impact on the KPIs your team members and partners have to meet. The tediousness of these tasks tends to lower employee productivity, lengthens processes, and introduces more room for miscalculations and incorrect data entry.

Here are a few key processes that you can automate:

- Vendor management: Analyzing and segmenting data and vendor activities at scale

- Contract management: Collecting contracts and setting up reminders for important deadlines or milestones

- Invoice management: Streamlining documents like receipts and purchase orders with accounting and purchase analysis tools

- Purchase orders: Building and track purchase orders

- Purchase requisitions: Centralizing activities for applying, approving, and tracking purchase requests

3. Nurture client relationships

Many of the risks discussed in this blog can stem from poor relationships with vendors and suppliers. Think of your client relationships as a consistent effort that needs to be prioritized at every stage of the procurement process.

You want to create an environment where your clients can trust and respect your business, and as a result, are motivated to give you honest, high-quality work. To have strong client relationships, you need to be communicative and transparent while conducting business. It’s important that your team has visibility at all times on contract terms, client performance, and payment activities. This gives you the resources to make timely payments, measure success correctly, and manage conflicts without making false assumptions.

4. Leverage e-procurement solutions

In the book ‘Trade Wars, Pandemics, and Chaos: How Digital Procurement Enables Business Success in a Disordered World,’ Dr. Elouise Epstein says that “digital procurement technology has evolved, the expectations for leadership regarding digital technology has changed, and the opportunity has arrived for those who are able to seize it.”

E-procurement solutions have become an important component of a company’s procurement strategy, especially after the COVID-19 pandemic. A survey by McKinsey discovered that the digital procurement solutions that have the highest impact on performance are those for analyzing spend, managing client relationships, automating source-to-pay workflows, and accelerating internal collaboration.

Each of these solutions supports companies in their efforts to monitor and prevent risk even if they’re managing hundreds of vendors, suppliers, and purchase orders.

DR. ELOUISE EPSTEIN

5. Invest in a digital adoption platform to support your procurement digitalization

Procurement digitization is a relatively new area of focus for most companies. This means internal employees and external clients now need to work with different tools they may not be familiar with. It can be overwhelming to keep up with new technology features and functionalities, especially when migrating complex processes to a new system.

Digital adoption platforms like Whatfix ensure that all users are empowered with the information they need to onboard and ramp up with new tools faster. This includes having 24/7 self-help resources that help employees, clients, and vendors navigate to the right places in a system, troubleshoot problems, and search for answers to tool-related questions.

6. Prioritize clear communication

Procurement is a highly-collaborative function that involves a wide network of participants. For example, your relationship with a vendor is also influenced by your vendor’s relationship with its suppliers.

That being said, the stakes are high. Miscommunication at the very start of the process can trickle down into detrimental errors that impact your revenue targets. By approaching your procurement processes in a strategic, systematic, and data-driven way, you can ensure that your teams have a single source of truth to inform their communication.

7. Track supplier performance

You can’t improve what you can’t measure, after all.

Tracking your supplier performance gives you the information you need to catch risks before it’s too late. You want to create performance goals and KPIs that align with what your business defines as success. This can include metrics like:

- Lead time

- Compliance rate

- Availability or emergency response times

- On-time delivery

- Product defect rate

Procurement risks can happen to anyone, but anyone can avoid them too.

With Whatfix, your business has the advantage of providing stellar digital experiences that can improve relationships with employees, vendors, and suppliers. A digital adoption platform protects your business processes against avoidable errors and unnecessary resistance toward change. You can use data-driven decision-making to create customized user flows that accelerate communication, prevent siloes, and boost engagement at work.

If you’re looking to build long-term trust with internal teams and external business partners, use Whatfix to elevate your procurement network by giving them more time and productivity back in their day.

Thank you for subscribing!